Cannabis Isolation & Crystallization Made Simple: Scalable Solutions for High-Purity Extracts

Root Sciences offers advanced cannabis isolation and crystallization equipment engineered for high-purity cannabinoid separation and consistent crystal formation. Our stainless-steel and glass-jacketed reactors are ideal for both small-batch R&D and large-scale CBD or minor cannabinoid isolation, providing optimal control over temperature, agitation, and filtration. Whether you’re refining crude hemp oil into pure CBD isolate or developing THCA crystalline extracts, our systems support scalable, repeatable workflows that meet the demands of pharmaceutical-grade production and compliance-driven cannabis labs.

Equipment Offerings

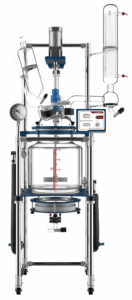

SR200f

The 200 L dual-jacketed stainless steel filter reactor is designed for efficient crystallization, filtration, and purification processes. Constructed from durable 316L stainless steel, this system offers precise temperature control with a dual-jacketed design, allowing for optimal heat transfer during CBD isolation. The built-in filtration system streamlines product separation, reducing processing time and improving overall yield. Ideal for large-scale production, this reactor ensures a seamless workflow for high-purity isolate manufacturing.

The CBD isolation process involves multiple steps, each designed to refine and purify the compound while removing unwanted components. These steps typically include:

- Extraction

- The process begins with extracting crude CBD oil from hemp or cannabis biomass. Common extraction methods include:

- CO₂ Extraction – Uses supercritical CO₂ to pull cannabinoids and other compounds from the plant material, resulting in a clean and solvent-free extract.

- Ethanol Extraction – Uses cold or warm ethanol to extract cannabinoids, followed by a refinement process to remove unwanted plant material.

- Hydrocarbon Extraction – Uses solvents such as butane or propane to extract cannabinoids, requiring post-processing to remove residual solvents.

- The process begins with extracting crude CBD oil from hemp or cannabis biomass. Common extraction methods include:

- Winterization & Filtration

- Once the crude CBD extract is obtained, it undergoes winterization, a process that removes fats, lipids, and waxes by dissolving the extract in ethanol and cooling it to sub-zero temperatures. The unwanted compounds solidify and are filtered out, leaving behind a refined CBD oil.

- Decarboxylation

- CBD naturally exists in the plant as CBDA, its acidic precursor. The oil is heated to convert CBDA into active CBD through a process called decarboxylation, ensuring that the final isolate is in its bioavailable form.

- Distillation

- To further refine the CBD extract, short path or wiped film distillation is used. This method separates cannabinoids based on their boiling points, removing residual plant compounds, terpenes, and unwanted cannabinoids such as THC. The result is a highly purified CBD distillate.

- Crystallization

- At this stage, CBD is isolated through crystallization, a controlled process that encourages pure CBD molecules to form solid crystals. The process typically involves:

- Solvent Mixing – The CBD distillate is dissolved in a solvent such as pentane or heptane, which helps separate CBD from other minor cannabinoids.

- Cooling & Nucleation – The mixture is cooled gradually, allowing CBD molecules to bond and form crystal structures.

- Filtration & Drying – The solid CBD crystals are filtered from the solvent and dried to remove any residual solvents, resulting in pure CBD isolate.

- At this stage, CBD is isolated through crystallization, a controlled process that encourages pure CBD molecules to form solid crystals. The process typically involves:

Why Choose CBD Isolate?

CBD isolate is widely used in various applications due to its purity and versatility. It contains zero THC, making it an attractive option for industries that require strict compliance with regulations. Benefits of using CBD isolate include:

- Versatility – Can be infused into oils, edibles, topicals, and pharmaceuticals without affecting flavor or aroma.

- Consistency – Ensures a standardized dose of pure CBD with each use.

- Zero THC – Ideal for consumers and industries that require a THC-free product.

- Long Shelf Life – Stable and resistant to degradation compared to full-spectrum extracts.

Optimizing the CBD Isolation Process

For large-scale production, specialized CBD isolation equipment is essential to maximize efficiency and yield. Advanced systems such as dual-jacketed reactors and filtration units allow for precise temperature control, efficient crystallization, and seamless separation of pure CBD.

Root Sciences provides cutting-edge CBD isolation equipment tailored for industrial processing. Our solutions streamline each step of the purification process, ensuring high-purity CBD isolate with consistent and reliable results. Whether you're scaling up production or refining your extraction workflow, we offer the technology and expertise to support your success in the CBD industry.

CO₂ extraction relies on the unique properties of carbon dioxide when it is pressurized and heated to specific conditions. Here’s a step-by-step breakdown of the process:

- Preparation of Biomass:

Cannabis or hemp plant material is ground to an optimal consistency to maximize surface area for extraction. - Pressurizing CO₂:

Carbon dioxide is pressurized and heated to its supercritical state, where it exhibits both liquid and gas properties. This allows it to efficiently dissolve cannabinoids and terpenes while leaving behind unwanted compounds. - Extraction Phase:

The supercritical CO₂ is passed through the biomass in an extraction vessel. The CO₂ acts as a solvent, pulling out cannabinoids, terpenes, and other desirable compounds. - Separation Phase:

The extracted compounds are separated from the CO₂ in a separator. The CO₂ is then recycled back into the system, making the process eco-friendly and cost-effective. - Post-Processing:

The resulting oil can be further refined or left as a full-spectrum extract, depending on the desired product.

CO₂ extraction is the preferred method for producing premium cannabis and hemp products, offering numerous advantages that set it apart from other extraction techniques. Here are the key benefits:

- Purity and Safety:

CO₂ extraction produces solvent-free cannabis and hemp extracts, ensuring no harmful residuals remain. This method guarantees the production of clean, high-quality oils that meet strict industry standards for safety and purity. - Full-Spectrum Extraction:

This method preserves cannabinoids, terpenes, and flavonoids, resulting in full-spectrum extracts that maintain the plant’s natural profile. These full-spectrum cannabis and hemp oils enhance the entourage effect and cater to a variety of product needs. - Eco-Friendly Process:

CO₂ is a natural, recyclable solvent, making the extraction process sustainable and environmentally friendly. Cannabis and hemp businesses benefit from reduced environmental impact while producing high-quality extracts. - Versatility:

CO₂ extraction enables the production of a variety of cannabis and hemp products, including full-spectrum oils, isolates, terpene-rich extracts, and concentrates. This versatility supports the growing demand for diverse product offerings in the cannabis and hemp industries. - Customization and Control:

CO₂ extraction systems offer precise control over temperature, pressure, and flow rate. This customization ensures efficient extraction of specific compounds, such as cannabinoids and terpenes, enhancing product quality. - Non-Toxic and Safe for Operators:

Unlike hydrocarbon methods, CO₂ extraction is non-toxic and non-flammable, providing a safer working environment for cannabis and hemp processors. - Scalability:

CO₂ extraction equipment is available in various sizes, supporting both craft cannabis processors and large-scale hemp extraction facilities. The scalability ensures businesses can expand operations seamlessly. - Reduced Post-Processing:

CO₂-extracted cannabis and hemp oils require minimal refinement, saving time and operational costs while delivering clean, ready-to-use extracts. - Preservation of Volatile Compounds:

Subcritical CO₂ extraction operates at lower temperatures, preserving delicate terpenes and ensuring flavor and aroma remain intact in cannabis and hemp extracts. - Recyclable Solvent:

The CO₂ used in extraction can be captured and reused, reducing costs and improving sustainability for cannabis and hemp businesses. - Regulatory Compliance:

CO₂ extraction meets strict cannabis and hemp industry regulations, producing extracts that are safe, reliable, and compliant with quality standards.

With these advantages, CO₂ extraction has become the go-to solution for cannabis and hemp processors looking to create premium oils, concentrates, and extracts that stand out in the market.

Crystallization is a post-extraction refinement technique used in cannabis and hemp processing to isolate cannabinoids—most commonly CBD and THCA—into solid crystalline form. This method enhances purity and consistency by converting cannabinoids into highly concentrated crystals, often exceeding 99% purity. Crystallized cannabinoids are ideal for pharmaceutical applications, vape products, and edibles that require precise dosing and a clean profile.

Crystallization is particularly popular for producing CBD isolate and THCA diamonds, as it allows processors to separate specific compounds from a complex mixture of cannabinoids, terpenes, and other plant materials. By carefully controlling temperature, solvent ratios, and agitation, manufacturers can promote uniform crystal growth and repeatable results, making this method essential for labs seeking high-performance cannabinoid refinement.

Crystallization in cannabis processing begins with a refined extract or winterized crude oil that contains the target cannabinoid—typically CBD or THCA. The extract is first dissolved in a suitable solvent, such as pentane or heptane, which helps create a supersaturated solution. Using jacketed glass or stainless-steel reactors, processors precisely control the cooling rate and agitation to trigger the nucleation and growth of cannabinoid crystals.

Over time, as the solution gradually cools and stabilizes, the cannabinoids begin to separate from the solvent and form solid crystalline structures. Once the desired crystal size and density are achieved, the mixture is filtered to separate the crystals from the remaining solvent. The final product is then dried and purged to remove residual solvents, resulting in pure, high-potency cannabinoid crystals ready for formulation or packaging.

This controlled process not only ensures high yields and purity but also allows manufacturers to scale production efficiently—making crystallization a critical step for cannabis labs focused on compliant, pharmaceutical-grade cannabinoid isolation.

Crystallization offers several key advantages for cannabis and hemp processors looking to achieve high-purity cannabinoid isolates. From increased product consistency to scalable production, here’s why crystallization is a preferred method in the cannabis industry:

1. High Purity Cannabinoid Isolation

Crystallization allows manufacturers to achieve purity levels exceeding 99%, making it ideal for producing pharmaceutical-grade CBD isolate or THCA crystalline. This level of purity is essential for formulations requiring consistent dosing and a clean cannabinoid profile.

2. Enhanced Product Consistency

By controlling parameters like temperature, solvent saturation, and agitation, crystallization delivers a uniform end product with predictable outcomes—crucial for both research and commercial production environments.

3. Scalable Process for Small and Large Batches

Crystallization workflows can be easily adapted to both laboratory-scale research and industrial-scale manufacturing. Equipment such as dual-jacketed filter reactors makes it possible to expand production without compromising on quality or control.

4. Solvent Recovery and Cost Efficiency

The solvents used during crystallization can be efficiently recovered and reused, reducing waste and operating costs while supporting sustainability goals.

5. Regulatory Compliance

The process enables cannabis labs to meet stringent regulatory standards for purity and safety, making it easier to certify products for medical, wellness, or adult-use markets.

6. Ideal for Formulation-Ready Products

Crystallized cannabinoids like CBD isolate and THCA diamonds are highly versatile. They can be easily integrated into a wide range of consumer products, including tinctures, topicals, edibles, and vape cartridges.