1. Where does the VKL 85 typically fit within a cannabis or hemp processing workflow?

The VKL 85 is commonly used after extraction and winterization as a primary refinement step for producing distillate at higher volumes. It is often selected by facilities that have outgrown smaller wiped-film systems and need more consistent throughput without moving into large industrial-scale equipment.

2. How does the VKL 85 differ from smaller wiped-film distillation systems?

Compared to smaller systems, the VKL 85 is designed to handle higher feed rates and sustained operation while maintaining the same wiped-film short-path principles. This makes it better suited for processors running longer production schedules or refining larger quantities of oil on a regular basis.

3. What types of processing facilities typically use the VKL 85?

The VKL 85 is commonly used by mid- to large-scale cannabis and hemp processors operating commercial distillation labs. It is well suited for facilities focused on steady daily production rather than intermittent or batch-style refinement.

4. How does feedstock preparation affect performance on the VKL 85?

Proper upstream preparation, such as effective winterization, filtration, and removal of residual solvents, plays an important role in how smoothly material runs through the system. Consistent feedstock preparation supports stable operation and predictable distillate output.

5. Why is wiped-film distillation often preferred at this scale?

Wiped-film distillation allows material to be processed continuously as a thin film, which supports efficient separation and repeatable results. At higher processing volumes, this approach helps maintain control and consistency compared to batch-based distillation methods.

6. How does operator visibility support day-to-day operation?

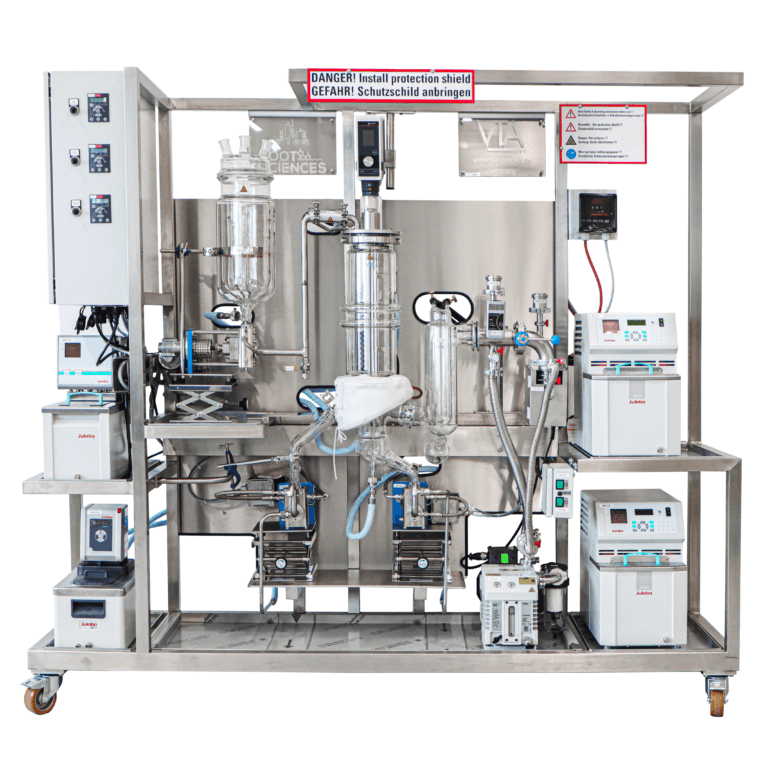

The VKL 85 includes visible process components that allow operators to observe film behavior and general operating conditions in real time. This visibility can assist with process understanding, adjustments, and maintaining stable performance over longer runs.

7. How is the VKL 85 typically integrated into existing lab infrastructure?

The system is usually paired with external vacuum systems, heaters, feed pumps, and downstream collection equipment. Its layout allows it to be incorporated into established processing lines without requiring major facility redesign.

8. What should processors consider when choosing a higher-capacity wiped-film system?

Processors often evaluate available floor space, desired throughput range, staffing and operator experience, and long-term production goals. Understanding how distillation fits into overall workflow planning is key when moving to higher-capacity systems.

9. How does the VKL 85 support consistent distillate quality over time?

When operated under stable conditions with consistent feed material, the VKL 85 is designed to support repeatable separation across ongoing production runs. This consistency is important for downstream formulation and product manufacturing.

10. Is the VKL 85 better suited for continuous or batch processing environments?

The VKL 85 is typically used in continuous or semi-continuous processing environments where predictable output and steady operation are preferred over batch-style distillation.