Premium Rosin Presses for Cannabis and Hemp

Root Sciences proudly partners with Sasquash to offer industry-leading rosin presses for solventless cannabis and hemp extraction. Built in Southern California and backed by a Limited Lifetime Warranty, Sasquash presses are known for their durability, high yield, and consistent performance. Whether processing flower, bubble hash, or dry sift, these solventless extraction machines are engineered for reliability and efficiency. With rugged construction and minimal maintenance requirements, Sasquash rosin presses are a trusted solution for operators seeking clean, high-quality concentrates.

Lab Scale

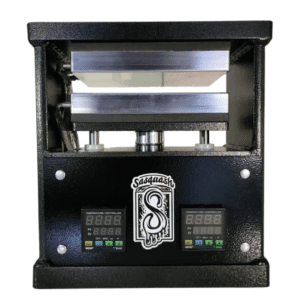

M2 Rosin Press

The M2 Rosin Press is a compact, manual solventless extraction machine designed for reliable and efficient rosin production. Ideal for small-scale operations or labs looking to produce high-quality concentrates, the M2 combines consistent pressure with user control to press flower, sift, or hash without the use of solvents. Its straightforward design and minimal footprint make it a practical option for operators who value clean extraction and mechanical simplicity. Built for durability and ease of use, the M2 is a trusted choice for producing solventless cannabis concentrates with clarity and quality.

V2 Rosin Press

The V2 Rosin Press is a durable, mid-sized press designed for producing rosin from cannabis or hemp flower, bubble hash, or sift. Its combination of pressing power and compact design makes it a practical fit for both personal use and small-scale commercial production. Built for consistent results and ease of operation, the V2 is ideal for processors looking to expand their solventless concentrate capabilities without transitioning to a fully automated setup. With minimal maintenance and straightforward controls, it delivers clean, high-quality rosin with every press.

Commercial Scale

10 Ton x YETI PRO SERIES

The 10 Ton X Yeti Pro Series is a heavy-duty rosin press built for processors who require higher pressure and greater control during solventless concentrate production. Designed for consistency and repeatability, it includes programmable settings for pressure, temperature, and pressing time—helping operators maintain quality across batches. Its sturdy frame and food-safe components make it a long-lasting option for serious producers working with flower, hash, or sift. With no air compressor needed and a built-in pressure gauge, the 10 Ton x Yeti Pro Series offers straightforward operation while meeting the demands of more advanced workflows.

Industrial Scale

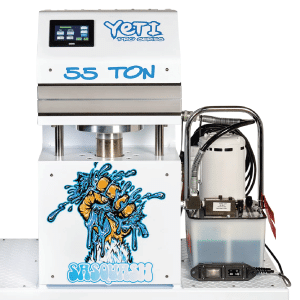

55 Ton x YETI PRO SERIES

The 55 Ton X Yeti Pro Series Rosin Press is built for high-volume solventless concentrate production, offering the force and control needed for demanding processing environments. Designed to handle large batches of flower, hash, or sift, this press supports consistent, repeatable results across extended production runs. With programmable settings and a rugged build, it provides operators with a reliable solution for scaling up rosin output while maintaining quality. Ideal for commercial labs or producers expanding their rosin extraction operations, the 55 Ton X Yeti delivers power, consistency, and ease of use.

200 Ton x YETI PRO SERIES

The 200 Ton X Yeti Pro Series Rosin Press is engineered for large-scale rosin production, offering the force required for high-throughput solventless concentrate processing. Suited for industrial operations, this press supports consistent extraction across substantial volumes of flower, hash, or sift. Its programmable settings and durable build make it ideal for facilities prioritizing efficiency, repeatability, and clean, solvent-free results. For processors scaling up operations, the 200 Ton X Yeti provides a dependable solution for meeting commercial output demands while maintaining quality standards.

Rosin extraction is a solventless method used to produce cannabis and hemp concentrates by applying heat and pressure to raw plant material. This process involves placing flower, hash, or sift between parchment paper and pressing it between heated plates. The pressure causes the resin to liquefy and separate from the plant material. No chemicals or solvents are used, making it a cleaner and more natural extraction method. The use of heat and pressure helps preserve valuable cannabinoids and terpenes. As a result, the final product is a full-spectrum concentrate with rich flavor and aroma. Rosin extraction is widely used for its simplicity, safety, and minimal post-processing requirements.

Rosin extraction is a solventless technique that relies on mechanical force rather than chemical solvents. The process is widely used in both small-scale and commercial settings due to its straightforward workflow and ability to preserve the natural compounds found in cannabis and hemp. While press models vary, the general method remains consistent across most equipment. Below is a step-by-step guide explaining how rosin press equipment is used to produce clean, high-quality concentrates.

1. Input

Begin by selecting and preparing the source material, such as cannabis flower, dry sift, or bubble hash. To reduce contamination and improve collection, the material is usually placed into a filter bag made from fine mesh. This bag is then placed between parchment paper, which keeps the rosin contained and prevents it from sticking to the heated plates during pressing.

2. Extraction

The parchment-wrapped material is positioned between the plates of the rosin press. Heat and pressure are applied at a controlled rate, typically over a short time window. The heat softens the resin glands while the pressure causes them to release, producing a viscous extract that flows onto the parchment paper.

3. Purification

Using a proper filter bag size and applying pressure evenly helps keep plant particles out of the final product. Consistent temperature control and clean pressing surfaces also contribute to higher purity. Together, these factors ensure that the rosin maintains clarity, texture, and cannabinoid content without the need for further processing.

4. Final Product

After pressing, the parchment paper is removed from the machine and allowed to cool slightly. The rosin is then collected from the paper using a dab tool or spatula. The end product is a solventless concentrate with a stable texture and full-spectrum profile, ready for immediate use or long-term storage.

Choosing the right rosin press depends on a range of operational factors, from the volume of material processed to the type of inputs used. Understanding these considerations can help operators make informed decisions that support long-term efficiency, product consistency, and safe processing.

1. Scale of Production

Consider how much material you plan to process on a regular basis. For personal use or small batches, compact manual presses may be sufficient. In contrast, commercial facilities typically require larger hydraulic or programmable units that support high-volume output. Matching the press size to your expected workflow helps prevent unnecessary strain on the equipment and ensures smoother production.

2. Pressing Techniques

Different materials and end products benefit from different pressing methods. Flower often requires higher heat and pressure for shorter durations, while hash or sift may need lower temperatures and gradual force to preserve terpene content. A rosin press should allow for fine control over pressure application to support a range of techniques.

3. Temperature Control

Accurate temperature settings are essential for preserving cannabinoids and terpenes. Presses with digital temperature control help maintain consistent results across batches. Even heat distribution across the plates also contributes to efficient extraction and a more uniform final product.

4. Plate Size and Pressure Capacity

The size of the plates determines how much material can be processed at one time. Larger plates can improve efficiency but require greater pressure to achieve complete extraction. It is important to ensure the pressure capacity of the press matches the size of the plates and the type of material being used.

5. Compliance and Certifications

For operators in regulated markets, equipment should meet safety and manufacturing standards. Features like UL-certified components, food-safe coatings, and consistent build quality help support compliance and reduce risk during inspections or audits.

6. Ease of Use and Maintenance

User-friendly interfaces, accessible components, and simple cleaning procedures can improve daily operation and reduce downtime. Presses that are easy to set up and maintain are especially beneficial for small teams or solo operators.

7. Cost-Effectiveness

While initial cost is a factor, it is also important to consider durability, maintenance needs, and the potential for long-term use. A press that can handle consistent output without frequent repairs or upgrades may offer better value over time.

8. Future-Proofing Features

As production needs grow, having a press that can scale with you is beneficial. Look for features such as programmable logic controllers, upgrade options for automation, or compatibility with larger pumps. These features provide flexibility to expand operations without replacing core equipment.

Rosin presses offer a clean, efficient method for producing cannabis and hemp concentrates without the use of chemical solvents. By applying controlled heat and pressure, rosin extraction preserves valuable compounds such as cannabinoids and terpenes, resulting in a full-spectrum concentrate with robust flavor and aroma. This solventless method minimizes post-processing requirements, reduces safety concerns, and supports compliance with increasingly strict extraction regulations. Because rosin presses operate mechanically, they are also relatively easy to maintain and can accommodate a wide range of input materials—from flower to bubble hash. For processors seeking a straightforward, chemical-free approach to concentrate production, rosin presses provide a practical and scalable solution.

1. What materials can I process with a rosin press?

Rosin presses are typically used to press cannabis or hemp flower, ice water hash (bubble hash), and dry sift. Each input material yields different results, with hash often producing the highest quality rosin.

2. How do I choose the right Sasquash press for my needs?

Choosing the right press depends on your volume, material type, and workflow. Smaller units like the M1 or M2 are ideal for home or boutique operations, while larger models like the V2 or X Yeti series support commercial-scale output.

3. Do I need an air compressor or other external equipment?

Most Sasquash presses come with a manual hand pump and do not require an air compressor. However, some larger units can be upgraded to support pneumatic or hydraulic pump systems if desired.

4. What’s the benefit of solventless extraction compared to other methods?

Solventless extraction offers a cleaner, more natural product without using chemical solvents. It's ideal for consumers seeking full-spectrum concentrates with robust flavor, aroma, and cannabinoid profiles.

5. How do I maintain my rosin press?

Routine maintenance includes cleaning the platens, checking for oil leaks or wear on moving parts, and following manufacturer guidelines. Proper care ensures consistent performance and extends the life of your equipment.

6. Are Sasquash rosin presses made in the USA?

Yes, all Sasquash rosin presses are manufactured and assembled in Southern California using high-quality components and UL-certified parts.

7. Do Sasquash presses come with a warranty?

Yes, Sasquash presses are backed by a Limited Lifetime Warranty, covering manufacturing defects and ensuring long-term reliability.

8. Can these presses be used in licensed processing facilities?

Absolutely. Sasquash presses are built to meet the needs of both licensed commercial processors and small-batch craft producers, offering consistent output and compliance-ready builds.