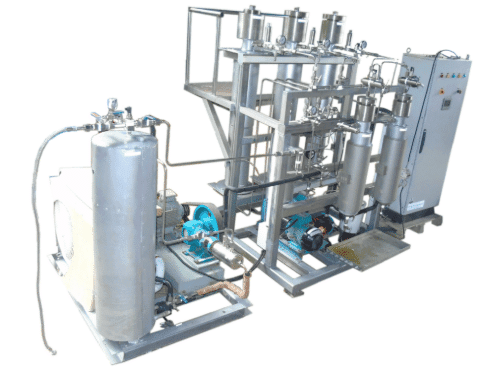

In search of potent, powerful, pure solvent-free extracts, supercritical CO2 extraction has emerged as an excellent standard. This technology is now revolutionizing sectors ranging from food and beverages to nutraceuticals and pharmaceuticals. Unlike the conventional methods using harsh chemicals, supercritical CO2 extraction provides an efficient, clean way of isolating the desirable compounds, thus ensuring that you get the final product of high quality.

Sections

ToggleWhat is Supercritical CO2 Extraction?

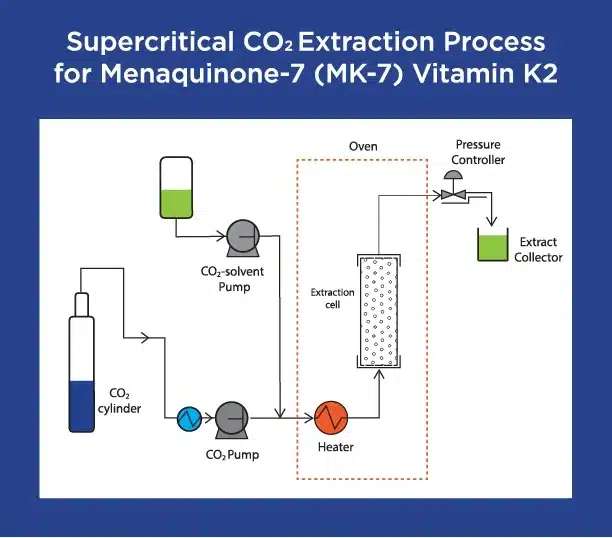

The method uses CO2 above its target temperature and pressure to go into the supercritical state. Here, it exhibits the intermediate properties between a liquid and a gas. When it reaches this state, CO2 can then penetrate matrices like a gas while at the same time dissolving compounds like a liquid. As CO2 is non-toxic in nature, it is also non-flammable, thus can be removed easily after extraction. It is also an excellent solvent for recovering sensitive bioactive compounds from various plants and raw materials.

Supercritical CO2 Extraction Process: Step-by-Step Guide

The supercritical CO2 extraction is a closed-loop process that is environmentally friendly as well as efficient. Below is a breakdown of the main stages involved in the process:

Step 1: Pressurization

At first, the CO2 gas is compressed and heated and brought to its critical point at achieve the supercritical condition. Here, CO2 acquires a density that allows it to behave as a solvent while retaining diffusivity like a gas. The pressurization process is then carefully controlled to a stable temperature and pressure.

Step 2: Loading the Raw Material

The raw plant material is dried and ground to have an increased surface area, which is then loaded carefully into a high-pressure vessel called the extraction chamber or cell. This is then appropriately sealed to withstand high pressure, thus creating a pleasant environment for the extraction process.

Step 3: Solubilization

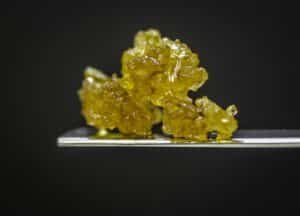

Supercritical CO2 flows or passes through an extraction vessel with the raw material. With proper pressure and temperature, CO2 diffuses in the matrix and then dissolves the target compounds, which are the cannabinoids, essential oils, and flavours, etc. Basically, the soluble nature of particular compounds depends on the density of CO2. Thus, particular extraction of a compound is possible by adjusting the temperature and pressure.

Step 4: Separation

Now, the CO2 is packed with dissolved extracts and flows in a separate vessel known as the separator. Here, the temperature and the pressure are lowered carefully. This transition causes CO2 to lose the solvating power, thus precipitating the compounds out from the solution. The CO2 is now ready for its final step, which is the collection.

Step 5: Collection & Recycling

Lastly, the precipitated extract is stored in the receiver vessel. The now-gaseous CO2 is then captured, cooled, recompressed, cleaned if required, and recycled into the system for further extraction. This recycling process enhances sustainability and reduces overall operational costs. The resultant extract gets down at the bottom and is removed for further processing. In the meantime, gaseous CO2 is passed through the condenser, where it gets cooled and converted to liquid form. The liquid CO2 is returned to its storage tank, which is ready to get re-pressurized and reused in the next extraction phase, making the extraction process cost-effective and sustainable.

Conclusion

In short, supercritical CO2 extraction is the peak of modern extraction processes that leverages the properties of CO2 in the supercritical state. It is a clean, powerful technique to get high-quality extracts from raw materials. It further delivers unmatched efficiency, purity, and selectivity. Because of its solvent-free, closed-loop nature, it not only ensures a safe and clean product but also aligns well with principles of green chemistry. As the demand for solvent-free and high-purity extracts in industries like nutraceuticals, pharmaceuticals, and cosmetics continues, supercritical CO2 is an ever-more critical player in the extraction process. It is the definitive method for industries that do not want to compromise on purity and quality.