Affordable, Scalable Distillation Solutions for Cannabis Processors

UIC wiped-film distillation systems offer a trusted, German-engineered solution for processors seeking consistent, high-purity cannabis and hemp distillate at a more accessible price point. Designed for efficiency and scalability, UIC equipment provides the same dependable short-path distillation technology found in premium systems—making it an excellent choice for producers looking to optimize performance without compromising on quality. Whether you’re launching a new extraction lab or expanding your post-processing capabilities, UIC delivers reliable throughput and repeatable results backed by Root Sciences’ expertise and global support network.

Lab Scale

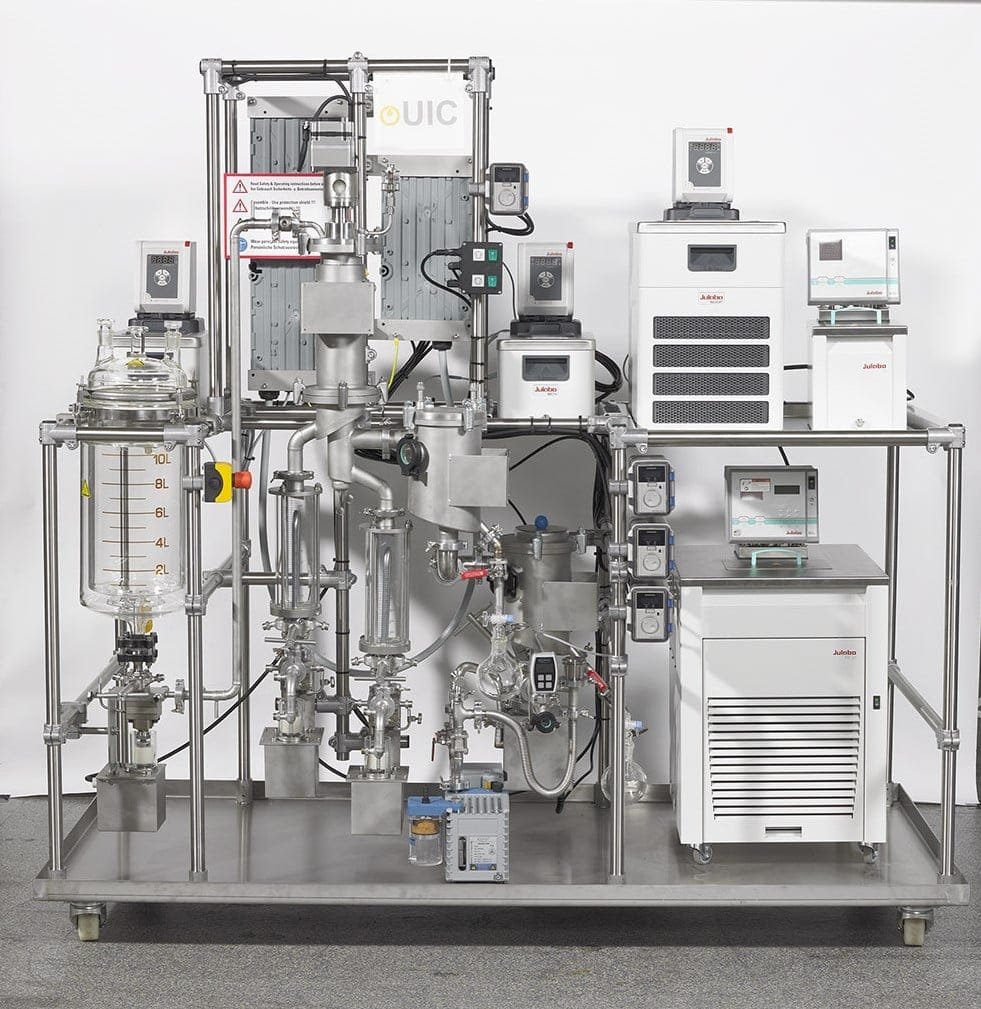

KDL5

The KDL5 is a wiped-film distillation system designed for the purification of cannabis and hemp oils. Its continuous operation and controlled processing environment allow for the efficient separation of cannabinoids, terpenes, and other components to produce a clean, high-purity distillate. Built for dependable performance in daily lab use, the KDL5 provides a practical solution for facilities focused on consistent output and product quality. Supported by Root Sciences, this system offers a straightforward approach to post-processing within the cannabis and hemp industries.

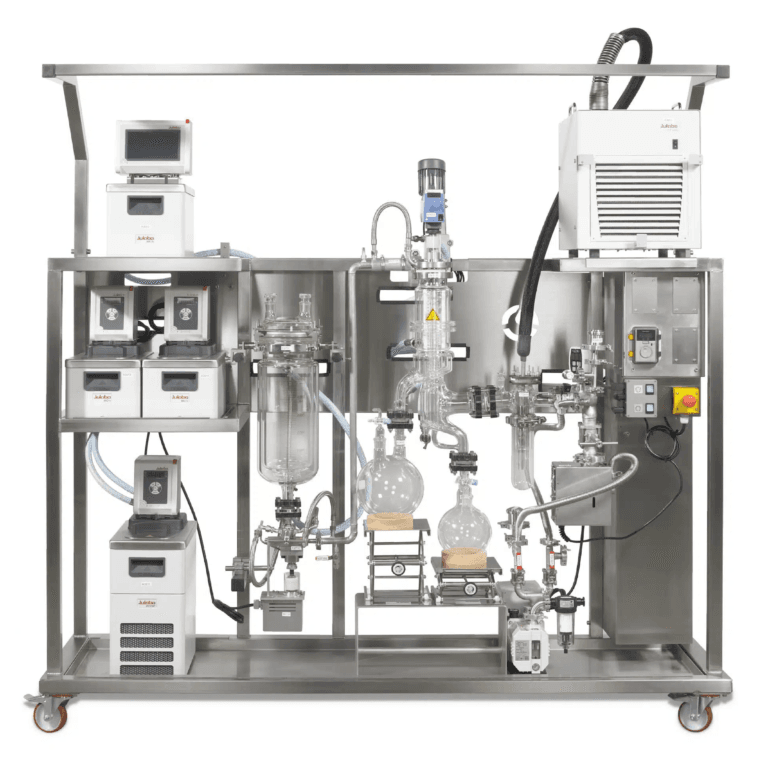

KD6

The KD6 is a compact wiped-film distillation system designed for refining cannabis and hemp oils into high-purity distillate. Engineered in Germany by UIC, it offers consistent performance in a smaller footprint, making it suitable for facilities focused on efficient, entry-level production. The system supports the separation of cannabinoids and other compounds to achieve a clean, golden distillate used in a range of finished products such as vapes, edibles, and tinctures. Supported by Root Sciences, the KD6 provides a practical solution for reliable and repeatable post-processing in cannabis and hemp applications.

Commercial Scale

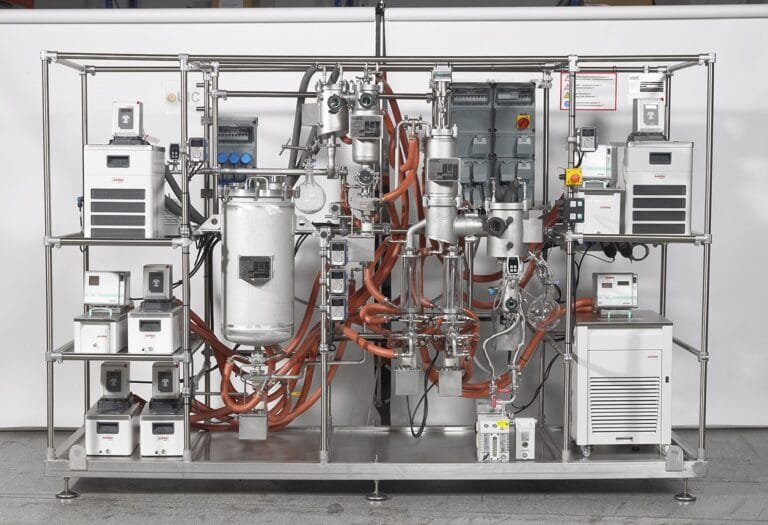

Coming Soon: KD10

The KD10 is a high-capacity wiped-film distillation system engineered for large-scale cannabis and hemp oil refinement. Designed and built in Germany by UIC, it supports continuous operation for consistent distillate production across demanding workflows. Its multi-stage design enhances efficiency and helps minimize product loss, making it suitable for facilities focused on higher throughput and dependable performance. Once available, the KD10 will expand Root Sciences’ UIC line with a robust solution for commercial-scale cannabinoid processing.

UIC wiped-film distillation systems are designed to refine cannabis and hemp oils into high-purity distillate through a continuous, controlled process. Built in Germany, these systems combine reliable performance with accessible pricing, giving processors an efficient option for post-processing at various production scales. From entry-level setups to higher-capacity operations, UIC equipment supports consistent cannabinoid recovery, streamlined workflows, and dependable daily use. Each system is supported by Root Sciences’ technical expertise, helping processors achieve the clarity, potency, and product quality expected in professional cannabis and hemp facilities.

Wiped-film, or short-path, distillation is a thermal separation technique that uses a thin film of oil spread across a heated surface under vacuum. The reduced pressure allows cannabinoids and other compounds to vaporize at lower temperatures, preserving delicate components and improving product purity. As vapors condense on an internal surface, they are collected separately from heavier materials left behind. This method is ideal for purifying cannabis and hemp extracts because it efficiently removes residual solvents, fats, and impurities while maintaining cannabinoid integrity. UIC systems apply this principle in a compact, automated format suitable for continuous operation in modern extraction labs.

| Model | Ideal For | Key Advantages | Facility Type |

|---|---|---|---|

| KDL5 | Entry-level production of cannabis and hemp distillate | Compact footprint, straightforward operation, consistent purity | Start-up labs or small-scale processors |

| KD6 | Medium-scale operations requiring higher throughput | Efficient continuous processing, reliable daily performance | Growing facilities and mid-size processors |

| KD10 (Coming Soon) | Large-scale cannabinoid refinement and commercial production | High-capacity system with multi-stage design for continuous operation | Established extraction facilities and high-volume producers |

UIC distillation systems provide processors with dependable performance, straightforward operation, and strong value across a range of production needs. Each unit is engineered for consistent distillate quality, making it easier to maintain uniform product batches over time. The compact design and efficient heat transfer help minimize product loss while improving processing speed. All systems are constructed from high-grade materials for durability and long service life. Whether used in a small-scale lab or a growing facility, UIC distillation equipment offers a balanced solution for achieving reliable cannabinoid refinement supported by Root Sciences’ global service and expertise.

1. Gentle thermal treatment of product

• UIC wiped-film systems use controlled temperatures that help minimize thermal stress on cannabinoids and terpenes during refinement.

• This gentle handling supports consistent distillate quality and reduces the likelihood of degrading sensitive compounds.

2. High level of customization & scale flexibility

• UIC offers multiple configuration options so processors can match system design to their workflow, throughput goals, and space constraints.

• The equipment is structured to support incremental scaling, allowing labs to adjust capacity as production needs grow.

3. Robust engineering & broad application experience

• UIC systems are built on decades of chemical and pharmaceutical distillation expertise, providing proven reliability in demanding environments.

• Their engineering approach supports stable, repeatable separation performance across a variety of cannabinoid-rich feedstocks.

4. High vacuum and effective separation/purification

• UIC distillation units achieve strong vacuum levels that enable efficient evaporation at lower temperatures, helping protect product integrity.

• This deep vacuum environment enhances the separation of cannabinoids from heavier compounds, supporting cleaner and more uniform distillate.

5. Support for process development, up-scaling & decision making

• UIC equipment is well-suited for R&D and pilot studies, allowing processors to refine distillation parameters before moving into larger routine production.

• The platform makes it easier to evaluate throughput, temperature profiles, and workflow needs when planning for scale-up.

6. Versatility for various feedstocks and regulated use

• UIC systems can accommodate different crude oil qualities, giving processors flexibility across biomass sources and extraction methods.

• Their designs can align with regulated or GMP-oriented environments, supporting compliance-driven production requirements.

7. Long-term reliability & performance

• UIC builds its systems with durable materials and industrial components intended for stable, long-term operation.

• This reliability helps reduce unplanned downtime and supports consistent distillate production over years of use.

Both VTA and UIC deliver German-engineered wiped-film short path distillation systems for cannabis and hemp processing. Each line focuses on producing clean, high-purity distillate through continuous, controlled separation. The right choice depends on your operating goals, budget, and scale.

Where VTA Excels

- Flagship performance: Designed for facilities that want a feature-rich platform with advanced controls and a long track record in cannabinoid refinement.

- Scalability for growth: Well suited for teams planning higher throughput, multi-shift operation, or integration with broader automation.

- Proven in the field: Adopted by producers who value repeatable results across demanding production schedules.

Where UIC Excels

- Value and accessibility: Built for teams seeking dependable wiped-film distillation at a more accessible price point.

- Compact options: Helpful when space is limited or when an operation wants an entry-level or mid-scale system that can run daily with minimal complexity.

- Straightforward operation: Practical for labs that want consistent distillate quality with clear workflows and easy onboarding.

How to Decide for Your Facility

- Production targets: If your roadmap includes higher throughput and advanced automation, VTA is often the better fit. For entry-level to mid-scale production with strong value, consider UIC.

- Budget and timeline: UIC supports a cost-conscious start while meeting quality goals for cannabis and hemp distillate. VTA aligns with facilities investing in premium features and long-term expansion.

- Footprint and utilities: UIC offers compact configurations for tighter spaces. VTA provides options that integrate well in larger, growth-oriented layouts.

- Team experience: Newer teams tend to appreciate UIC’s approachable operation. Seasoned teams may prefer VTA’s advanced capabilities and configurability.

Bottom Line

Both VTA and UIC produce reliable, high-purity cannabis and hemp distillate with continuous operation and strong repeatability. Choose the line that best aligns with your current scale, future growth plans, and budget, and Root Sciences will support you through selection, installation, training, and ongoing maintenance.

1. Who is UIC, and what role do they play in cannabinoid distillation?

UIC is a German engineering company specializing in wiped-film short-path distillation systems used to refine cannabis and hemp extracts into clean, consistent cannabinoid distillate. Their equipment is known for durable construction and approachable workflows suited for both emerging and established labs.

2. What makes UIC distillation systems different from VTA systems?

UIC systems emphasize accessibility, visibility, and hands-on operation through glass and stainless-steel configurations, while VTA systems focus more on large-scale production and advanced automation. Both offer reliable performance, but they serve different processing preferences and workflow styles.

3. What types of products can be made using distillate from UIC equipment?

Distillate produced on UIC wiped-film systems is commonly used in vape formulations, edibles, tinctures, capsules, beverages, topicals, and other infused cannabis and hemp products.

4. Are UIC wiped-film systems suitable for labs new to distillation?

Yes. UIC offers systems like the KDL5 and KD6 that provide clear visibility, straightforward controls, and manageable operating requirements, making them ideal for teams learning the distillation process or expanding into refinement for the first time.

5. Do UIC systems require specialized installation or utilities?

Most UIC units integrate easily into standard processing environments, using familiar utility connections and compact layouts that fit well within typical cannabis and hemp refinement spaces.

6. How does UIC distillation help maintain cannabinoid quality?

UIC wiped-film systems use controlled temperature zones and short residence times to gently separate cannabinoids from heavier materials, helping preserve sensitive compounds and reduce thermal degradation.

7. What throughput ranges do UIC systems offer?

UIC equipment covers a range of production needs—from the lab-scale KDL5 to larger stainless-steel systems like the KD6 and KD10—allowing processors to match system size to their workflow and scale as production increases.

8. What customization or upgrade options are available?

UIC systems can be enhanced with gear pumps, touch-screen control interfaces, cold-trap improvements, larger feed vessels, and compliance-focused documentation to support diverse operational needs.

9. How difficult is routine maintenance on UIC equipment?

Maintenance is user-friendly, with straightforward cleaning, seal checks, and vacuum system monitoring. Preventive Maintenance Kits are available to simplify scheduled component replacements and reduce downtime.

10. Does Root Sciences provide support for UIC distillation systems?

Yes. Root Sciences offers installation assistance, operator training, troubleshooting, and access to replacement parts and maintenance kits to ensure long-term, reliable system performance.