Cannabis concentrates are the most popular forms known for their potent effects. Bubble hash and rosin are two widely preferred, high-quality, chemical-free cannabis concentrates. While both are powerful and flavorful extracts produced without using any dangerous solvents, they differ in texture and the overall user experience.

This comprehensive guide explores bubble hash vs rosin differences and their unique characteristics.

Sections

ToggleWhat Is Bubble Hash?

Bubble hash is a solventless cannabis concentrate created by separating trichomes from plant material using ice water and agitation. This cannabis extract is light blonde to dark brown with a crumbly appearance.

Appearance, Texture & Use

Bubble hash has a sandy, granular texture ranging from powdery to slightly sticky, depending on quality grade. It’s commonly consumed by smoking, vaporizing, or pressing into rosin for further refinement.

How Is It Made?

To produce bubble hash, cannabis flowers are put in specialized bags and soaked in ice water. The mixture is then agitated to break away trichomes and filtered through progressively finer mesh screens. The filtered trichomes are dried and cured to create the final bubble hash product.

What Is Rosin?

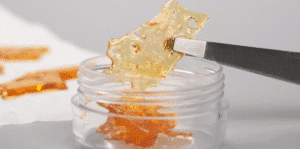

Rosin is a solventless, high-quality cannabis concentrate produced using a simple mechanical device known as a rosin press. This cannabis extract can be made by simply applying heat and pressure to cannabis flower, hash, or kief.

Appearance, Texture & Use

Depending on the starting cannabis material, rosin can have varied textures from a clear, sap-like consistency to a buttery and opaque one. Rosin is typically consumed by dabbing, vaporizing, or adding to flowers for enhanced potency.

How Is It Made?

To produce rosin, cannabis material is placed between parchment paper and then subjected to controlled heat (160-220°F) and pressure using a rosin press. The applied heat and pressure melt the cannabinoids and terpenes, creating a potent extract. The process is quick and produces rosin immediately without curing time.

Bubble Hash vs Rosin: Key Differences

Factor | Bubble Hash | Rosin |

Extraction Method | Ice water separation and filtration | Heat and pressure application using rosin press |

Purity & Terpene Retention | Moderate purity, some terpene loss during drying and curing process | High purity, excellent terpene preservation |

Potency & Effects | 40-70% THC, clean effects | 60-90% THC, full-spectrum effects |

Flavor& Aroma | Earthy, hash-like flavors | Robust, strain-specific flavors with full spectrum terpene profile |

Yield and Efficiency | 10-20% yield, material dependent | 15-25% yield, more predictable |

Equipment and Cost | Bags, buckets, basic equipment | Rosin press, higher initial investment |

Storage and Shelf Life | Longer shelf life when properly dried | Shorter shelf life, requires refrigeration |

Which One Should You Choose?

We understand that the choice of bubble hash vs. Rosin can be confusing. It comes down to your priorities, experience level, and intended use.

Choose Bubble Hash if you:

- Want a traditional hash flavor and effects

- Stable cannabis concentrate that’s easier to store

- Prefer a solventless process like ice water extraction

- Want a cost-effective entry into solventless concentrates

Choose Rosin if you:

- Expect maximum potency and terpene preservation

- Want immediate concentration without drying and curing processes

- Prefer dabbing and vaping

- Looking for a simpler home-based process, such as a hairdryer

Conclusion

The choice between bubble hash and Rosin is about personal preferences and intended use. Both are pure cannabis extracts with no solvent contamination.

Bubble hash is a traditional, affordable concentrate offering maximum potency and terpene preservation. It provides premium dabbing experiences. Rosin is a more flavorful extract offering potency and a full-spectrum terpene profile. Consumers should consider flavor, potency, and storage requirements when choosing between the two concentrates. For producers, the complexity of the production method becomes a priority.