The cannabis industry is undergoing a fast evolution due to the adoption of technological innovations from other sectors. One such method is ultrasonic extraction, which produces high-quality concentrates. The method leveraging properties of sound waves can efficiently extract cannabinoids, terpenes, and other bioactive compounds from cannabis plant material.

This article explores ultrasonic extraction and how it produces superior yields and acts as an environmentally friendly operation.

Sections

ToggleWhat Is Ultrasonic Extraction?

Ultrasonic extraction is a technique that uses high-frequency sound waves (typically 20-200 kHz) to disrupt plant cell walls, enhancing the release of bioactive compounds. This extraction process employs acoustic cavitation, which involves creating millions of microscopic bubbles utilizing rapid pressure fluctuations, which then collapse violently, generating intense shear forces that break down cellular structures of plant materials.

Key Equipment:

- Ultrasonic Generator: It is a high-power electronic unit that converts electrical energy into ultrasonic frequencies.

- Ultrasonic Probe/Sonotrode: A titanium probe that transmits ultrasonic energy directly into the extraction medium.

- Processing Vessel: A stainless steel container is used to hold the cannabis-solvent mixture during ultrasonication extraction. It features cooling jackets for temperature control.

Why Use Ultrasonic Extraction for Cannabis?

There are several reasons to consider ultrasonic extraction:

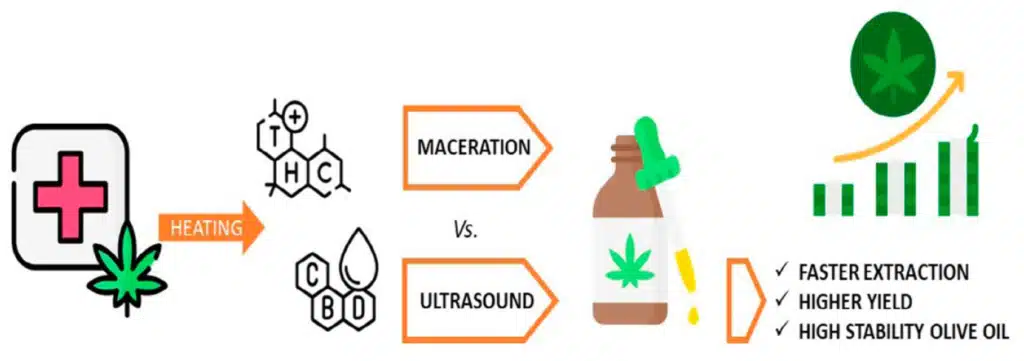

- Higher Yields – Ultrasonic extraction can achieve 15-30% higher cannabinoid recovery rates compared to conventional methods such as solvent cannabis extraction.

- Rapid Processing – Dramatically reduces processing time from hours to minutes. Typically, the extraction cycle requires only 5-15 minutes.

- Temperature Control – The process is a low-temperature operation (30-60°C) that preserves heat-sensitive terpenes and prevents degradation.

- Solvent Flexibility – Ultrasonic extraction is compatible with several solvents, including ethanol, olive oil, coconut oil, water, and even solventless applications.

- Energy Efficiency – Compared to more sophisticated extraction methods such as CO₂ or hydrocarbon extraction, it consumes less energy, reducing environmental impact.

The Ultrasonic Extraction Process (Step-by-Step)

Depending on the size of your operation, you can choose scale to operation, but the core steps of the method remain the same.

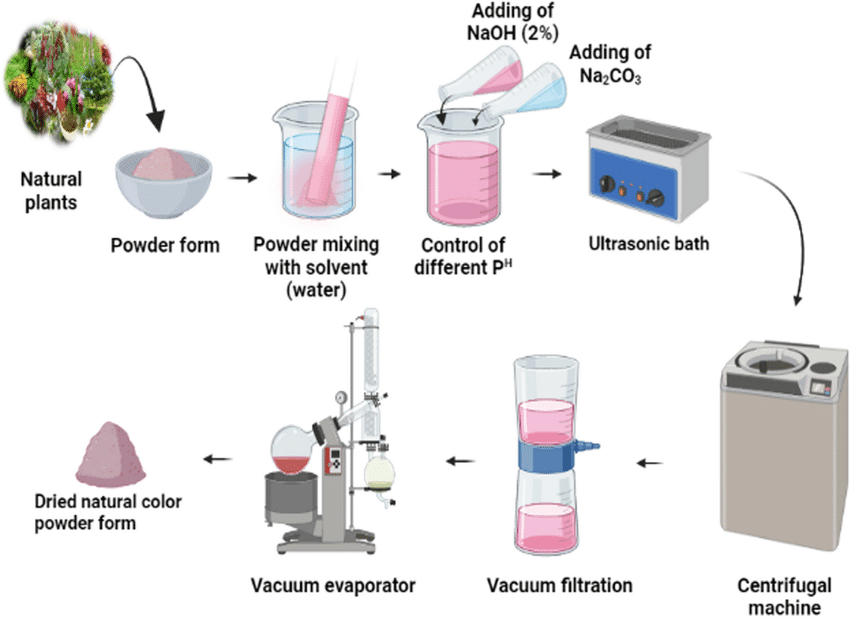

- Preparation

Cannabis material is cleaned and broken into smaller sizes to maximize surface area. If activated cannabinoids are required, decarboxylation may be performed at 115°C for about 40 minutes. Also, the ultrasonic extractor is calibrated to appropriate frequency and amplitude settings based on batch size and target compounds.

- Mixing

Prepared plant material is mixed with the solvent of choice in the processing vessel, typically in a 10:1 solvent-to-plant material ratio. The ultrasonic probe is immersed in the solution.

- Ultrasonic Treatment

The ultrasonic extractor probe is activated at predetermined amplitude settings (typically 60-70%). Ultrasonication extraction proceeds for 5-15 minutes at a constant temperature below 60°C through cooling systems.

- Filtration

The mixture is strained through fine mesh screens post-extraction to remove larger plant particles. For high-quality purity, a secondary filtration is performed using Whatman Grade 1 filter paper to remove remaining particulates.

- Post-Processing

Extracts are then separated from the solvent using rotary evaporation at controlled temperatures.

Ultrasonic vs. Traditional Cannabis Extraction Methods

Method | Solvent Used | Yield | Time | Cost | Pros | Cons |

Ultrasonic | Ethanol/Oil/Water | 85-95% | 5-15 min | Low | Fast extraction, efficient, preserves terpenes, low temperature | Initial equipment investment is high |

CO₂ | Supercritical CO₂ | 80-90% | 2-8 hours | High | Clean, no residuals | Expensive equipment, high pressure risks |

Ethanol | Ethanol | 70-85% | 4-24 hours | Medium | Simple process, scalable, economic for commercial operations | Requires winterization, fire hazard |

Hydrocarbon | Butane/Propane | 75-90% | 1-6 hours | Medium | High potency extracts, economical for commercial production | Safety concerns, requires purging to remove solvent |

Solventless | None | 60-75% | 30-60 min | Low | No solvents, pure extracts | Lower yields, labor intensive |

Choosing the Right Ultrasonic Extractor for Cannabis

To fully benefit from the ultrasonic extraction process, you must select the right ultrasonic extraction. Here are some considerations:

1. Power Output (Wattage)

Higher-wattage ultrasonic extractors, typically 1500-3000W, can process larger batches and achieve faster extraction times for commercial operations.

2. Frequency

Operating frequencies between 20-40 kHz provide optimal cavitation effects for cannabis cell disruption without excessive heat generation.

3. Scalability

Choose modular ultrasonic extraction systems, which can easily scale from laboratory (200-500W) to industrial (3000W+) processing capabilities.

4. Material Compatibility

Choose ultrasonic extractors with titanium probes and stainless steel components for compatibility with most solvents. They also resist corrosion during ultrasonic extractions.

5. Automation & Safety Features

Advanced ultrasonic extractor systems with automated controls can help better control temperature monitoring and provide safe operation features such as safety shutoffs.

Challenges and Considerations

If you are interested in adopting ultrasonic extraction, here are some challenges to consider:

1. Initial Equipment Cost

Quality ultrasonic extraction equipment comes at a significant upfront investment ($5,000-$50,000+) depending on the scale of operation you are targeting.

2. Learning Curve

Ultrasonic extraction is a sophisticated process, and understanding the optimal parameters for different cannabis strains requires training and experimentation.

3. Regulatory Compliance

Ultrasonic extraction operations must meet local cannabis regulations regarding equipment certification, safety protocols, and product testing requirements.

Conclusion

Ultrasonic extraction is a significant advancement in cannabis processing technology. Saving energy, offering a cleaner extraction alternative, and unparalleled efficiency, speed, and quality make it a process that provides rapid processing and environmental sustainability. As a producer, you will have an edge by adopting ultrasonic extraction, as you can achieve superior product quality and operational efficiency.

While initial investment is a concern, the versatility of ultrasonic extractors to work with various solvents and their scalability make them ideal for businesses of all sizes.