Entry-Level Distillation Built for Real Results

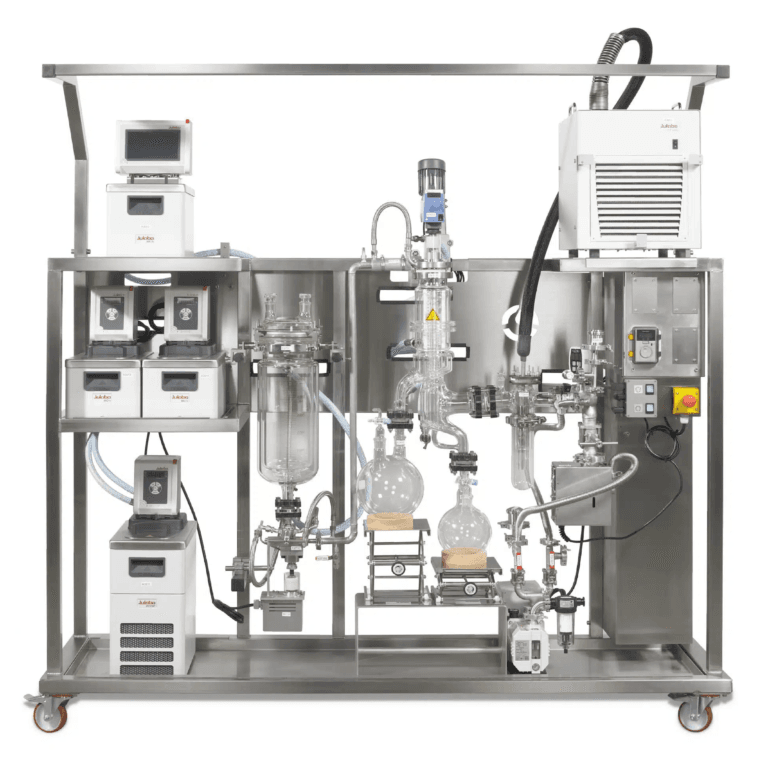

The KDL5 is a glass wiped-film distillation system designed as an affordable, user-friendly starting point for labs entering cannabis and hemp distillation or scaling on a budget.

- Typical Throughput: 1.3 L/h

- Affordable option for new or growing labs

- Glass design for clear process visibility

- Semi-continuous feeding for smooth operation

- Engineered by UIC in Germany

| Dimensions: | 6.6' x 2.3' x 6.6' (2.0 x 0.7 x 2.0 m) |

| Power: | 1-phase, 240 V, 60 A, 60 Hz or 3-phase, 400 V, 25 A, 50 Hz |

- UL ready (all necessary individual components are UL listed)

The KDL5: Reliable Distillation for Growing Cannabis Labs

Built to support small and mid-size cannabis and hemp processors with a straightforward, transparent distillation process

The KDL5 is a compact wiped-film distillation system designed for cannabis and hemp processors who need a reliable way to produce clean, high-quality distillate without the complexity or cost of larger units. Its glass construction provides full visibility into the distillation process, helping operators monitor separation in real time and better understand how material behaves during refinement. As an accessible entry point into short-path distillation, the KDL5 is well suited for labs that are just beginning to process cannabinoids or expanding their capabilities on a budget. It supports semi-continuous operation and produces distillate commonly used in vapes, edibles, tinctures, and topicals. Optional upgrades—such as discharge gear pumps, larger feed vessels, and cold-trap enhancements—allow processors to tailor the system to their workflow as production grows. Overall, the KDL5 offers a dependable foundation for achieving consistent distillate quality in cannabis and hemp extraction environments.

Wiped-film short-path distillation is a gentle purification method widely used in cannabis and hemp processing to refine crude extracts into high-quality cannabinoid distillate. During the process, a thin film of oil is spread across a heated surface while internal wipers keep the layer uniform, allowing desirable compounds to evaporate quickly without being exposed to high temperatures for long periods.

Because the vapor travels only a short distance before it condenses, wiped-film short-path distillation reduces thermal stress and helps preserve sensitive cannabinoids that are important for THC and CBD products. The result is a cleaner, more consistent distillate that can be used in vapes, edibles, tinctures, topicals, and other infused cannabis and hemp products, making this technique a core step in modern post-extraction refinement.

The KDL5 uses a wiped-film short-path distillation process that gently separates cannabinoids from heavier compounds without exposing the material to unnecessary heat or long residence times. Its glass design allows operators to see the evaporation and condensation steps as they happen, making it easier to understand the workflow and make informed adjustments. This transparency helps new processors learn the distillation process while supporting consistent, clean distillate production for a variety of end-use products.

1. Clear visibility into the distillation process

2. Ideal for labs entering cannabinoid distillation

3. Consistent short-path separation for cleaner distillate

4. Compact footprint for limited lab space

5. Supports semi-continuous operation

6. Upgradeable as workflows expand

7. Engineered by UIC in Germany

1. What is the main purpose of the KDL5?

The KDL5 is designed to provide a reliable entry point into wiped-film short-path distillation, helping cannabis and hemp processors produce clean, refined cannabinoid distillate.

2. Why does the KDL5 use glass components?

Its glass design allows operators to clearly see the evaporation and condensation steps in real time, making it easier to monitor performance and understand the distillation process.

3. What types of products can be made with KDL5 distillate?

Distillate produced on the KDL5 is commonly used in vapes, edibles, tinctures, topicals, and a wide range of infused cannabis and hemp products.

4. Is the KDL5 suitable for smaller labs?

Yes. The KDL5 is compact, approachable, and budget-friendly, making it an excellent choice for labs that are new to distillation or expanding their processing capabilities.

5. Does the system support continuous operation?

The KDL5 uses a semi-continuous feeding setup that allows smoother processing and reduces the need for frequent manual intervention.

6. Are there upgrade options available?

Yes. Optional upgrades include discharge gear pumps, a larger feed vessel, enhanced cold-trap components, and GMP documentation to support compliance-focused facilities.

7. How difficult is it to operate the KDL5?

The system is designed to be user-friendly, with clear visibility and straightforward controls that make learning and day-to-day operation easier for both new and experienced technicians.

8. What kind of maintenance does the KDL5 require?

Routine cleaning and inspection are simple, and Preventive Maintenance Kits are available to help labs replace essential parts on a predictable schedule and minimize downtime.

9. What type of throughput can the KDL5 support?

The KDL5 is built for small-batch and mid-sized refinement runs, giving labs an efficient and consistent way to produce high-quality distillate at an entry-level scale.

10. Is the KDL5 made with durable materials?

Yes. The system is engineered by UIC in Germany and built with high-quality stainless steel, borosilicate glass, and robust components designed for long-term reliability.