In a world with industrial separation and purification, gentleness and efficiency are very important, mainly when dealing with high-value or heat-sensitive materials. Wiped Film Distillation is a superior technology that meets this criterion. A high vacuum is used for operations and is a unique film spreading mechanism, where wiped film distillation offers a controlled method of separating components as per their boiling points. Here in this article, we will delve into this technique’s process, principles, and applications, understanding why it is the preferred choice across different sectors.

Sections

ToggleWhat is wiped film distillation?

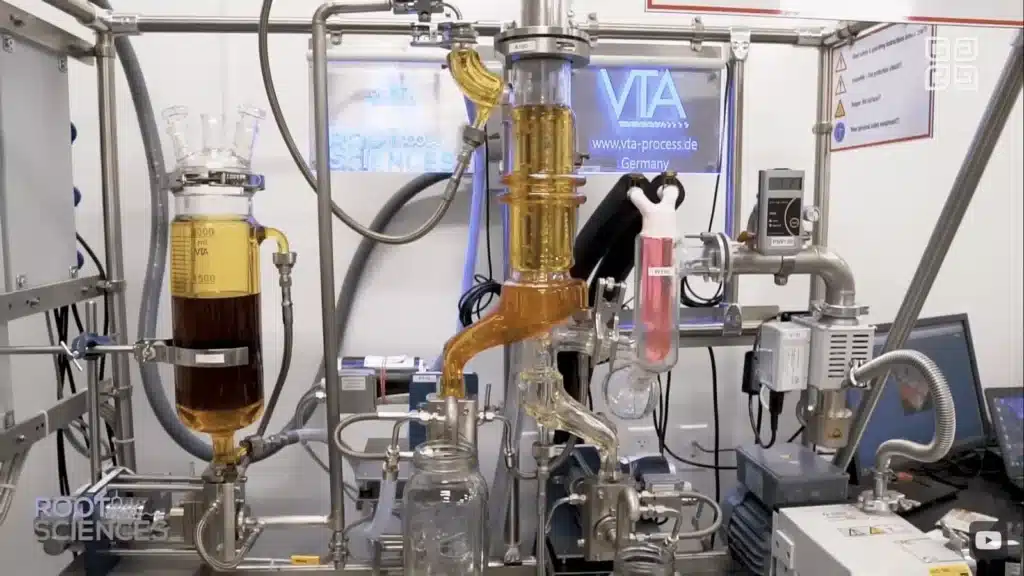

Wiped Film Distillation is the short-path separation method that operates under controlled temperature and high vacuum. In this technique, feed material is spread in a turbulent, thin film over a heated area by a rotating wiper. This whole setup allows for fast evaporation of the volatile elements that then travel short distances to a condenser. And the result is highly efficient separation of mixtures based on boiling points.

Key Points:

- This technique is perfect for viscous, heat sensitive materials

- It is a process that enables higher throughput as well as consistency when compared with other batch techniques

- This method ensures reduced thermal stress because of short exposure time as well as low operating temperature

The Process of Wiped Film Distillation

How It Works

Wiped film distillation can be broken down into steps like:

- Feed material: The slurry or liquid feed is there at the top of the vertical evaporation cylinder

- Film formation: A rotor is there with wiper blades that spreads the feed in a thin, turbulent and uniform film over heated inner surface of the cylinder

- Evaporation: High vacuum and heat causes volatile components to vaporize fast from thin film

- Vapor path: The vaporized molecules travel a small distance to the internal condenser that is located at the center of the unit, a place where they re-liquefy

- Collection: The light and heavy fractions, i.e., condensed distillate and unvaporized residue, are collected in different outlets at the bottom of the still

Components of a Wiped Film Evaporator

1. Still / Evaporation Surface

This is a cylindrical heated area where the liquid film is formed and then evaporated. Its internal wall provides thermal energy that is required to vaporize the material’s thin film.

2. Wiper System

These are the mechanical rollers or blades that spread the feed in a uniform film, thus preventing any buildup. This ensures proper heat transfer as well as prevents material from degrading or settling on hot surface.

3. Feed System

These are the inlets and pumps that introduce the raw material into the evaporator in a controlled way. Consistent and controlled feed rate maintains a uniform and stable film.

4. Residue & Distillate Outlets

It is the separate exit points that are there for purified distillate and heavy by-products. The distillate outlet takes the condensed, purified vapor and the residue outlet removes all unvaporized, concentrated fraction.

5. Vacuum System & Cold Trap

This is the high vacuum system, which lowers down the boiling points when a cold trap captures the volatile vapors.

6. Heating System

This system offers uniform, precise heat to the evaporation area for better processing. It further delivers uniform and precise temperature control that is important for sensitive materials.

Principles behind the Process

The actual effectiveness of Wiped Film Distillation is rooted in 3 main principles, which are:

1. Heat transfer efficiency

This agitated, thin film reduces thermal resistance, thus allowing for fast and efficient heat transfer from the wall to the material.

2. Low thermal stress on sensitive compounds

The quick residence time of material in the heated zone reduces the threat of thermal decomposition.

3. Continuous vs. batch operation

Wiped Film Distillation is continuous, thus allowing for regular feed and product collection, enhancing operational consistency and throughput as compared to the batch processes.

Types of Wiped Film Systems

- Wiped Film– It is the standard system where the wipers spread material into a thin film for better evaporation.

- Rolled Film– This uses rollers rather than blades for gentle film spreading, which is ideal for delicate compounds.

- Short Path Distillation includes an internal condenser placed close to the evaporation surface for short vapor travel and high purity.

Advantages of Wiped Film Distillation

Wiped Film Distillation provides a nice set of benefits over the traditional distillation processes, like pot stills or falling film evaporators.

- Gentle processing for sensitive compounds: Low operating temperatures and short residence time help to preserve the molecular integrity of the thermally labile compounds like essential oils, vitamins, and cannabinoids.

- High purity and yield: Efficient separation and less hold-up volume lead to superior purity of distillate and a higher recovery rate of target compounds.

- Efficient separation: The thin, turbulent film makes a constantly renewed and large surface area, resulting in a great heat and mass transfer rate, allowing for the separation of the components with close boiling points.

- Continuous operation: The continuous nature of the process thus allows for huge volumes to be processed without any downtime associated with recharging and cleaning batch systems, therefore improving overall productivity.

- Scalability: The procedure is scalable from small lab-scale units for research and development to huge industrial systems, thereby allowing for flawless technology transfer.

Applications of Wiped Film Distillation

- Pharmaceuticals: WFD is used for purification of pharmaceutical ingredients

- Cannabis & Hemp: it is the primary method to produce high-purity cannabinoid distillates such as THC and CBD by removing the waxes, fats, chlorophyll, and impurities

- Essential Oils & Flavors: WFD refines and concentrates the delicate compounds from the plants without losing the volatile top notes or changing their profiles

- Specialty Chemicals: The process of WFD purifies the polymers, monomers, oils, and other chemicals, where the traditional methods may cause some decomposition or discoloration

- Food Industry: WFD concentrates the Omega 3 fatty acids from fish oils, recovers flavors, and distills the vitamins.

Key Considerations for Process and Application

Applying WFD successfully needs careful attention to many factors such as:

- Material Properties: Thermal sensitivity, the feed material’s boiling point, and the viscosity influence the system design and operating parameters.

- Vacuum & Temperature Control: Control over vacuum and heating media temperature is essential to achieve the desired separation efficiency and product quality.

- Operational Costs: The original capital investment and maintenance of mechanical wiper system and vacuum pump can be higher for simpler systems.

- Batch vs Continuous: While the WFD process is continuous, choosing between it and batch processing depends on production volume, operational flexibility, and material characteristics.

Future Trends in Wiped Film Distillation

Looking at what the future holds when it comes to WFD, here are some trends:

- Automation and Digital Controls– AI-driven monitoring results in better efficiency and consistency.

- Sustainability: huge focus on energy efficiency heating systems and solvent recovery.

- Growing Industrial Adoption: more demand in cannabis, pharmaceuticals and specialty chemicals.

Conclusion

WFD or wiped film distillation is the premier modern separation technology that offers an unmatched blend of efficiency, precision, and gentleness. Its capability to handle most challenging materials like botanical extracts and complex pharma compounds makes it an invaluable tool across various sectors. By facilitating high-purity products, constant operation, and scalability, WFD not only meets the present demands of the industry. Still, it is poised to play an important part in future innovations in the manufacturing and purification sectors.