This article is intended strictly for educational and informational purposes. It does not provide operational instructions or guidance for performing BHO extraction.

Advanced BHO extraction techniques are used in licensed and regulated environments to improve extract purity, terpene preservation, and operational efficiency. Rather than focusing on manual intervention, modern BHO extraction emphasizes system design, quality control, and safety-first engineering. Understanding these techniques provides insight into how professional-grade concentrates are produced consistently and responsibly.

Sections

ToggleWhat is BHO Extraction

BHO extraction refers to the use of hydrocarbon solvents to separate cannabinoids and terpenes from cannabis or hemp biomass. In professional environments, BHO extraction methods are built around closed systems, controlled conditions, and rigorous quality standards. These approaches support the production of various concentrate formats while addressing safety concerns in BHO extraction.

There are different types of BHO products available today, including shatter, badder, wax, live resin, sauce, and crystalline concentrates. Each product type reflects specific processing and post-processing decisions rather than a single extraction approach.

Advanced Pre-Processing Techniques

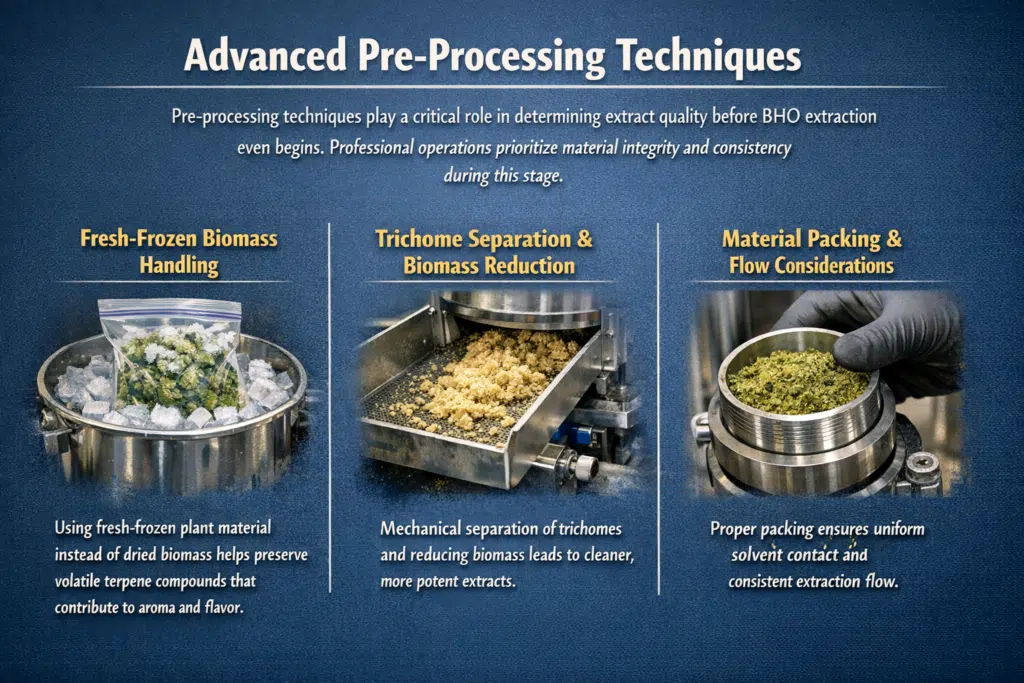

Pre-processing techniques play a critical role in determining extract quality before BHO extraction even begins. Professional operations prioritize material integrity and consistency during this stage.

1. Fresh-Frozen Biomass Handling

Using fresh-frozen plant material instead of dried biomass helps preserve volatile terpene compounds that contribute to aroma and flavor. This approach is commonly associated with live extract products and is valued for maintaining a profile closer to the original plant.

2. Trichome Separation and Biomass Reduction

Some facilities employ mechanical separation methods in controlled environments to concentrate trichomes prior to extraction. Reducing excess plant material can lead to cleaner extracts and more efficient solvent interaction.

3. Material Packing and Flow Considerations

Uniform material preparation supports consistent solvent contact and minimizes uneven flow paths. These considerations help improve extraction consistency and reduce variability between batches.

High-Efficiency BHO Extraction Techniques

Advanced BHO extraction techniques rely on engineered systems designed to maximize control, efficiency, and repeatability.

1. Closed-Loop Extraction Systems

Closed-loop systems contain solvents throughout the extraction process and allow for solvent recovery and reuse. This approach improves efficiency, reduces waste, and directly addresses safety concerns in BHO extraction by limiting environmental exposure.

2. Solvent Selection and Behavior

Different types of gas for BHO extractions are selected based on their chemical properties and compatibility with the desired product outcome. These decisions influence extraction selectivity and final concentrate characteristics without requiring manual adjustments.

3. System-Assisted Flow and Recovery

Professional systems are designed to maintain stable solvent movement and efficient recovery. These capabilities improve throughput while supporting consistent extraction performance across multiple runs.

Advanced Post-Processing Techniques

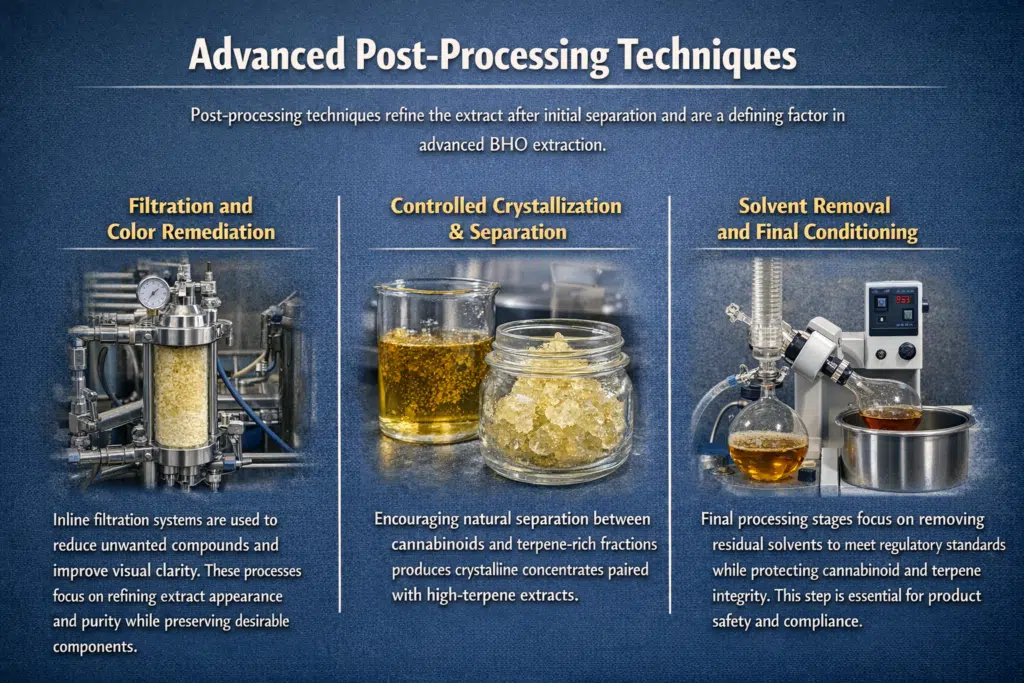

Post-processing techniques refine the extract after initial separation and are a defining factor in advanced BHO extraction.

1. Filtration and Color Remediation

Inline filtration systems are used to reduce unwanted compounds and improve visual clarity. These processes focus on refining extract appearance and purity while preserving desirable components.

2. Controlled Crystallization and Separation

Certain BHO products are created by encouraging natural separation between cannabinoids and terpene-rich fractions. This results in products such as crystalline concentrates paired with high-terpene extracts and contributes to the wide range of different types of BHO available.

3. Solvent Removal and Final Conditioning

Final processing stages focus on removing residual solvents to meet regulatory standards while protecting cannabinoid and terpene integrity. This step is essential for product safety and compliance.

Automation and Safety Techniques in BHO Extraction

Automation is a cornerstone of modern BHO extraction techniques. Automated systems continuously monitor operational conditions, improve repeatability, and reduce the risk of human error.

Safety concerns in BHO extraction are addressed through certified equipment, engineered facilities, ventilation systems, and strict operational protocols. Compliance-driven design ensures that extraction environments are built specifically to handle flammable solvents safely.

Quality Control and Troubleshooting BHO Extraction

Quality assurance programs rely on laboratory testing, documentation, and process monitoring. Troubleshooting BHO extraction in professional settings focuses on identifying system deviations, material inconsistencies, or maintenance issues rather than making reactive changes.

Analytical testing supports consistency, verifies solvent removal, and ensures that final products meet established quality benchmarks.

BHO Extraction Tools and Product Consumption

BHO extraction tools used in professional environments include closed-loop systems, recovery units, filtration assemblies, and analytical instruments. These tools are designed for regulated facilities and are not intended for unlicensed use.

For consumers, BHO consumption methods vary depending on product type and formulation. Common formats are designed for vaporization or controlled use, with labeling and testing providing important safety information.

Conclusion

Advanced BHO extraction techniques are defined by system-level control, safety engineering, automation, and quality management rather than manual procedures. As the industry continues to evolve, these techniques support consistent production, regulatory compliance, and the growing diversity of BHO-based products.

Understanding these concepts helps explain how modern extraction facilities produce high-quality, full-spectrum concentrates while prioritizing safety and consistency.

FAQs

Advanced BHO extraction techniques are used in licensed facilities to improve extract consistency, preserve terpene profiles, and reduce contamination risks. These techniques focus on system design, automation, quality control, and safety compliance rather than manual processing.

Advanced BHO extraction techniques are designed to address safety concerns in BHO extraction through closed systems, engineered facilities, and automated monitoring. While no extraction process is risk-free, professional environments significantly reduce hazards compared to unregulated methods.

Yes, advanced BHO extraction techniques influence clarity, texture, terpene retention, and overall consistency. These techniques help produce stable and predictable outcomes across different types of BHO without relying on aggressive processing.

Consumers can look for lab-tested products, clear labeling, and certificates of analysis that include residual solvent data and terpene profiles. Products made using regulated BHO extraction methods are more likely to meet safety and quality standards.

No, color alone is not a reliable indicator of quality. High-quality BHO is better evaluated through lab testing, aroma, stability, and cannabinoid and terpene content rather than appearance alone.

BHO extraction is only legal in licensed and regulated facilities, and laws vary by region. Unauthorized BHO extraction poses serious legal and safety risks, which is why commercial operations must meet strict compliance requirements.