BHO extraction is a hydrocarbon-based process used in licensed cannabis and hemp facilities to produce concentrated products with high potency and strong terpene profiles. Because the process relies on flammable solvents, professional-grade equipment, proper ratings, and strict safety systems are essential. This guide provides a comprehensive overview of the core tools used in BHO extraction, why they matter, and how they support quality, compliance, and safety in regulated environments.

Understanding BHO extraction tools is also critical for minimizing risk, improving consistency, and reducing downtime caused by avoidable equipment issues.

Sections

ToggleHow to Craft Connoisseur-Grade Butane Hash Oil

Connoisseur-grade concentrates are the result of controlled workflows rather than shortcuts. In professional environments, consistency is achieved through standardized equipment selection, validated BHO extraction methods, and disciplined post-processing. These factors directly influence aroma, texture, and stability across different types of BHO.

Advanced BHO extraction techniques typically focus on tighter control of process variables, improved solvent management, enhanced filtration, and documented quality assurance practices. Facilities that invest in proper tools and systems are better positioned to deliver repeatable, high-quality results while meeting regulatory expectations.

Solvents: Propane and Butane Gas

The most common types of gas for BHO extractions used in professional facilities include n-butane, isobutane, and propane. Each solvent has different physical characteristics that affect selectivity, volatility, and terpene preservation. Solvent choice also determines how equipment must be rated, monitored, and maintained.

Solvent purity, proper storage, and accurate documentation are critical components of safety concerns in BHO extraction. Regulated operations typically address these factors through detailed SOPs, regular audits, and engineering controls designed to reduce ignition and exposure risks.

Professional Tools for BHO Extraction

Below is a numbered overview of the most common professional tools used in BHO extraction. These descriptions focus on purpose, quality considerations, and operational relevance rather than instructions.

1. Biomass Grinder

A biomass grinder prepares plant material into a consistent size range, which supports uniform solvent contact and predictable processing. Inconsistent grinding is a common factor when troubleshooting BHO extraction issues related to flow irregularities or uneven outcomes between batches.

2. Biomass Packer

Biomass packers help load extraction columns evenly and consistently. Proper packing improves repeatability and reduces channeling, which supports more stable BHO extraction methods in commercial workflows.

3. Closed-Loop Extraction Equipment

Closed-loop extraction equipment is the industry standard for professional BHO extraction. These systems contain solvent within a sealed environment, supporting solvent recovery, reduced waste, and improved safety. Equipment must be correctly rated for pressure, temperature, and facility classification requirements.

4. Hoses

Extraction-rated hoses transport hydrocarbons between system components. They must be chemically compatible and pressure-rated for the application. Hose degradation, incorrect ratings, or improper inspection are frequent contributors to safety concerns in BHO extraction.

5. Gaskets

Gaskets provide seals at connection points throughout the system. Material compatibility and routine inspection are critical, as worn gaskets can lead to leaks that escalate into major operational and safety issues.

6. Fittings

High-quality fittings ensure secure connections and system integrity. Many facilities standardize fittings to simplify maintenance, reduce failure points, and improve inspection readiness during audits.

7. Ball Valves

Ball valves allow controlled routing and isolation of flow paths. Smooth operation, proper ratings, and regular inspection help reduce mechanical failure and support consistent performance across BHO extraction methods.

8. Inline Color Remediation Column

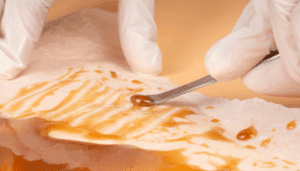

Inline color remediation columns are used in some workflows to support filtration and refinement goals. From a quality assurance standpoint, these tools are evaluated based on consistency targets and contaminant-risk management rather than appearance alone.

9. Refrigerant Scale

A refrigerant scale supports accurate measurement during solvent handling and recovery-related activities. Accurate measurement improves consistency, reduces waste, and strengthens compliance documentation.

10. Sight Glasses

Sight glasses provide visual confirmation of process conditions within the system. They are useful for early detection of abnormalities and play a role in troubleshooting BHO extraction without unnecessary disassembly.

11. Vacuum Pump

Vacuum pumps are used in post-processing and solvent removal systems. Routine maintenance, performance verification, and cleanliness are essential for meeting product quality and safety standards.

12. Vacuum Oven

Vacuum ovens support finishing processes by managing temperature and pressure under controlled conditions. In professional operations, validation, monitoring, and recordkeeping are as important as the oven itself.

13. Ventilation and Explosion-Proof Fan

Ventilation design is one of the most critical safety concerns in BHO extraction. Explosion-proof fans, appropriate airflow design, and classified electrical systems reduce ignition risk and support safer working environments.

14. PPE and Safety Equipment

Personal protective equipment includes eye protection, chemical-resistant gloves, protective clothing, and respiratory protection when required. Gas detection, emergency shutoff systems, and safety training are equally important components of a comprehensive safety strategy.

15. Tool Box and Maintenance Kit

A dedicated tool box helps keep inspection-ready tools organized and calibrated. Preventive maintenance is a key factor in reducing downtime and avoiding repeated troubleshooting BHO extraction problems.

16. Packaging Tools and Storage

Packaging tools and storage solutions affect product stability, terpene retention, and consumer usability. Packaging also plays a role in compliance labeling and influences how products align with different BHO consumption methods.

BHO Extraction Methods and Why Tools Matter

BHO extraction methods vary based on facility design, regulatory requirements, product goals, and scale of operation. Regardless of method, professional tools support controlled solvent handling, repeatable workflows, and safer operations. When equipment is mismatched, poorly maintained, or improperly rated, quality issues and safety concerns in BHO extraction increase significantly.

Troubleshooting BHO Extraction in Professional Environments

In licensed facilities, troubleshooting BHO extraction is handled through documentation and verification rather than guesswork. Common issue categories include:

- Mechanical wear and seal integrity

- Measurement and calibration inconsistencies

- Inadequate maintenance schedules

- Environmental control issues such as ventilation or temperature stability

- Quality system gaps including cleaning and inspection records

Treating troubleshooting as a structured quality process improves long-term reliability and compliance.

Different Types of BHO and Market Expectations

Different types of BHO are commonly categorized by texture, appearance, and aroma profile. Market expectations focus on consistency, cleanliness, and terpene expression. Tool selection, filtration strategies, and finishing controls all influence how stable and repeatable these outcomes are across batches.

BHO Consumption Methods and Packaging Considerations

BHO consumption methods vary depending on product format and consumer preference. Packaging choices influence oxidation risk, terpene preservation, and usability. For brands, packaging also supports product differentiation and regulatory presentation.

High-Quality Tools for High-Quality Concentrates

Professional results are achieved through the right combination of properly rated equipment, documented maintenance, calibrated measurement, and safety-first facility design. Investing in high-quality tools reduces operational disruptions and supports consistent outcomes across all BHO extraction methods.

FAQs

In licensed facilities, the most important professional tools for BHO extraction typically include closed-loop extraction equipment, extraction-rated hoses and fittings, reliable gaskets and valves, solvent measurement tools, post-processing tools like vacuum pumps and vacuum ovens, and safety systems such as ventilation and gas detection. These tools support consistency, compliance, and safer operations.

The biggest safety concerns in BHO extraction involve flammable solvent handling, vapor management, leak prevention, ignition control, and proper facility classification. Professional operations reduce risk through explosion-proof ventilation, rated equipment, routine inspections, PPE, gas detection, and documented SOPs.

The most common types of gas for BHO extractions in professional environments include n-butane, isobutane, and propane. Solvent choice affects equipment ratings, monitoring needs, and process control requirements, which is why regulated facilities emphasize solvent documentation, purity standards, and safe storage protocols.

Troubleshooting BHO extraction often involves checking seal integrity, hoses, gaskets, fittings, valve performance, calibration accuracy, and maintenance history. Environmental factors like ventilation performance and temperature stability can also contribute. Most facilities troubleshoot by documenting symptoms, verifying equipment condition, and correcting issues through validated maintenance steps.

Different types of BHO are typically categorized by texture, clarity, and terpene intensity. Final consistency is influenced by raw material quality, equipment capability, filtration choices, and post-processing controls. Because of this, tool selection can directly affect product stability and repeatability across batches.

BHO consumption methods vary by product format and user preference, which is why packaging and storage matter for stability and terpene preservation. Proper packaging helps reduce oxidation, protects texture, and supports compliance labeling requirements, especially for terpene-rich concentrates.