Troubleshooting BHO extraction is essential for maintaining product quality, operational safety, and regulatory compliance. Most issues encountered during BHO extraction are not isolated failures. They are usually the result of recurring variables such as temperature instability, equipment integrity problems, solvent handling errors, ventilation gaps, or inconsistent starting material.

This article on common issues and troubleshooting in BHO extraction focuses on identifying symptoms, understanding likely causes, and improving diagnostic oversight across modern BHO extraction methods. The content is intended for quality control, safety review, and process evaluation rather than operational instruction.

Sections

Toggle1. Nucleation and Lipids

Nucleation is one of the most common quality issues in BHO extraction and often presents as buddering, sugaring, or cloudy concentrates. This behavior is closely associated with lipids and waxes that become co-extracted with cannabinoids.

Common issues

- Texture instability during storage

- Loss of clarity in otherwise clean extracts

- Inconsistent product behavior across batches

Likely causes

- Elevated wax and lipid content from biomass

- Variability in plant material quality

- Temperature or handling inconsistencies

Troubleshooting focus

- Review material sourcing and preparation standards

- Evaluate filtration and handling practices used during Bho extraction

- Consider how lipid behavior differs across different types of BHO

2. Improper Purging of Butane

Residual solvent is one of the most critical troubleshooting concerns in BHO extraction. Inadequate solvent removal can impact flavor, stability, and consumer safety.

Common issues

- Bubbling or popping in the finished product

- Sharp or chemical odor

- Failed residual solvent compliance testing

Likely causes

- Inconsistent purge environment

- Vacuum system integrity issues

- Uneven extract distribution

Troubleshooting focus

- Inspect purge system performance and documentation

- Review purge outcomes within established BHO extraction methods

- Address residual solvent as a core safety concern in BHO extraction

3. Temperature Fluctuations During Extraction

Temperature stability plays a major role in extraction selectivity and final product quality. Fluctuations can increase the solubility of unwanted compounds.

Common issues

- Dark or green-tinted extracts

- Reduced terpene retention

- Inconsistent results between runs

Likely causes

- Environmental temperature variation

- Inadequate monitoring or calibration

- Equipment thermal limitations

Troubleshooting focus

- Improve temperature monitoring during Bho extraction

- Align thermal controls with specific BHO extraction methods

- Review how advanced BHO extraction techniques prioritize temperature consistency

4. Equipment Leaks

Equipment leaks pose both safety risks and performance inefficiencies in BHO extraction systems.

Common issues

- Pressure instability

- Solvent odor in the workspace

- Reduced recovery efficiency

Likely causes

- Worn seals or gaskets

- Improper fittings or connections

- Material incompatibility

Troubleshooting focus

- Inspect and maintain critical BHO extraction tools

- Evaluate seal compatibility with types of gas for BHO extractions

- Maintain documented inspection and maintenance schedules

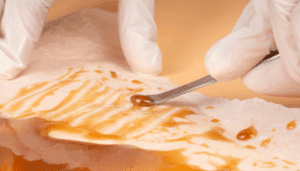

5. Over-Extraction or Under-Extraction

Balancing extraction intensity is essential for both yield and quality. Errors in either direction can lead to recurring production problems.

Common issues

- Harsh flavor and dark color from over-extraction

- Low cannabinoid recovery from under-extraction

Likely causes

- Inconsistent run conditions

- Improper material loading

- Misalignment between process and product goal

Troubleshooting focus

- Review consistency across Bho extraction runs

- Align extraction approach with target different types of BHO

- Standardize quality checks across operators

6. Contamination from External Sources

Contamination issues are frequently mistaken for extraction failures when they originate from handling, storage, or the surrounding environment.

Common issues

- Failed contaminant testing

- Off-odors or foreign particulates

- Reduced shelf stability

Likely causes

- Improperly cleaned BHO extraction tools

- Cross-contamination between work areas

- Inadequate material storage controls

Troubleshooting focus

- Strengthen sanitation and handling protocols

- Separate clean and processing zones

- Document contamination prevention practices

7. Blockages in the System

Blockages can disrupt solvent flow, create pressure instability, and reduce overall extraction efficiency.

Common issues

- Restricted solvent movement

- Unexpected pressure changes

- Inconsistent recovery performance

Likely causes

- Excess plant particulates

- Resin buildup over time

- Inadequate filtration

Troubleshooting focus

- Inspect filters and system pathways

- Review material preparation standards

- Integrate blockage prevention into routine Bho extraction maintenance

8. Inadequate Ventilation

Ventilation is a foundational requirement for safe BHO extraction operations and is closely tied to facility compliance.

Common issues

- Solvent vapor accumulation

- Alarm triggers or inspection failures

- Unsafe working conditions

Likely causes

- Insufficient air exchange

- Poor facility airflow design

- Inadequate monitoring systems

Troubleshooting focus

- Evaluate ventilation within broader safety concerns in BHO extraction

- Review airflow design during Bho extraction planning

- Ensure monitoring and alarm systems remain operational

9. Decarboxylation Errors

While decarboxylation occurs outside the core extraction phase, errors at this stage are frequently misattributed to BHO extraction problems.

Common issues

- Inconsistent potency

- Terpene degradation

- Labeling discrepancies

Likely causes

- Excessive thermal exposure

- Inconsistent time control

- Poor separation of extraction and post-processing records

Troubleshooting focus

- Track time and temperature exposure separately from BHO extraction methods

- Review post-processing logs when troubleshooting BHO extraction outcomes

- Align practices with intended BHO consumption methods

10. Crafting Quality BHO

Consistently producing high-quality concentrates requires a systems-based approach rather than reactive corrections.

Common issues

- Batch variability

- Equipment-related downtime

- Compliance challenges

Likely causes

- Lack of process standardization

- Incomplete documentation

- Inconsistent operator training

Troubleshooting focus

- Document and standardize Bho extraction workflows

- Maintain and audit BHO extraction tools regularly

- Integrate quality control throughout the Bho extraction lifecycle

Conclusion

Troubleshooting BHO extraction is about recognizing patterns, controlling variables, and prioritizing safety. By addressing common failure points such as temperature instability, equipment integrity, solvent handling, ventilation, and post-processing alignment, operators can improve consistency across all Bho extraction methods.

As extraction technology continues to evolve, combining proven Bho extraction fundamentals with advanced BHO extraction techniques remains essential for scalable, compliant, and high-quality production.