In the food processing and cannabis industry, separation and purification processes play a crucial role. To bring efficiency to the process, a wiped film evaporator – a sophisticated equipment designed to handle heat-sensitive materials is utilized. If you plan to achieve precision and efficiency to maintain high purity, you need to understand the working principle of the wiped film evaporator.

In this guide, we delve deeper into the operation, applications, and advantages of wiped film evaporators.

Sections

ToggleWhat Is a Wiped Film Evaporator?

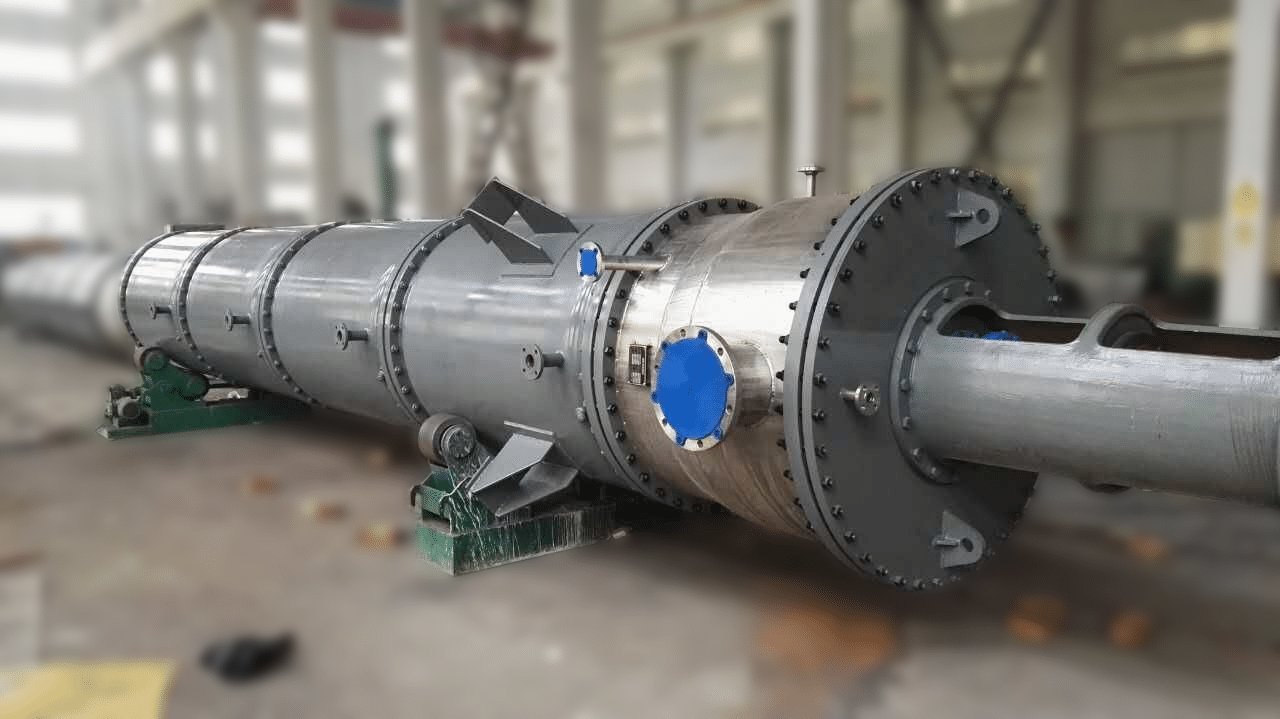

A wiped film evaporator is a thermal separator that uses mechanical wipers or blades to spread a liquid feed material into a thin, uniform film across a heated cylindrical surface. These evaporators are more efficient than conventional evaporators because they ensure continuous movement, as opposed to the conventional method, where materials sit in pools or pass through slowly. Additionally, the vacuum in wiped film evaporators lowers boiling points, making processing thermally sensitive compounds more efficient.

Working Principle of Wiped Film Evaporator

To truly benefit from the efficiency of these evaporators, a thorough understanding of the working principle of the wiped film evaporator is essential. It enables you to optimize performance and troubleshoot operational issues.

- Feed Introduction: Source material is introduced into the evaporator through the feed inlet. The flow is controlled to ensure even distribution of the material in the heated cylindrical body.

- Film Formation: Rotating wipers spread the incoming feed into a thin, uniform film (typically 0.1-2mm thick). Contact of the film with the heated internal wall of the evaporator maximizes the surface area contact.

- Heat Transfer and Evaporation: The heated surface rapidly evaporates the volatile compounds from the thin film. Also, the wiped film evaporator working principle ensures continuous film renewal, preventing localized overheating.

- Vapor and Residue Separation: Vapors from the evaporator are passed to the condenser system, while non-volatile residue flows downwards along the wall.

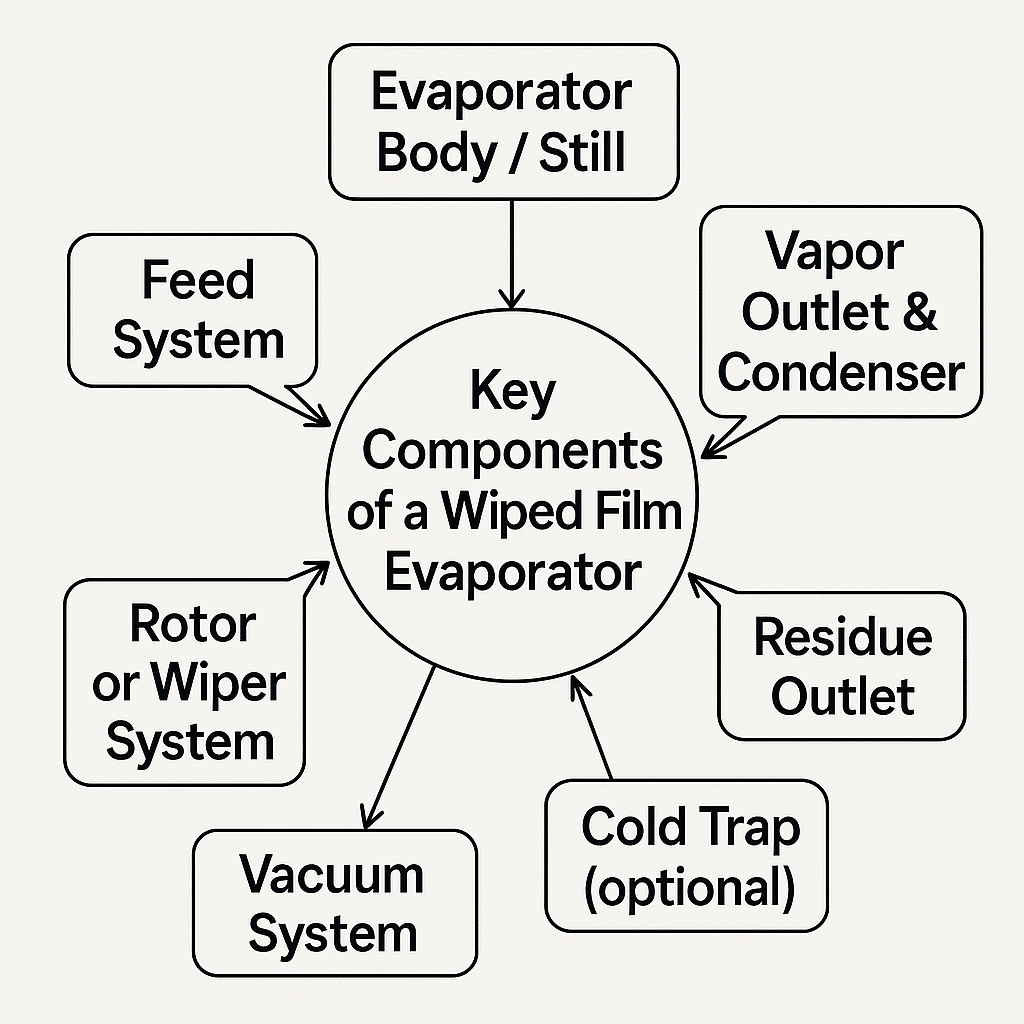

Key Components of a Wiped Film Evaporator

A wiped film evaporator is a complex machine with several components. Here are the key elements:

- Evaporator Body / Still: It is the main cylindrical vessel with a jacketed heating surface, typically constructed from stainless steel or borosilicate glass.

- Rotor or Wiper System: A set of blades attached to a central rotating shaft, preventing fouling and maintaining optimal heat transfer.

- Feed System: A controlled inlet mechanism of pumps, flow meters, and a preheating vessel to feed material into the evaporator at a consistent rate.

- Vapor Outlet & Condenser: An outlet port that directs evaporated vapors to a condensation system for distillation and condensation.

- Residue Outlet: A discharge port at the bottom of the wiped film evaporator to collect concentrated residue.

- Vacuum System: A pump system that creates and maintains reduced pressure within the evaporator, essential for lowering boiling points.

- Cold Trap (optional): A chilled chamber positioned between the evaporator and vacuum pump to prevent vapors from escaping.

Design and Construction

To choose a quality wiped film evaporator, it is essential to understand the design and construction that make it reliable.

- Construction Materials: The construction material is selected based on chemical compatibility and operating conditions. Most industrial wiped film evaporators are constructed from 316L stainless steel. At the same time, borosilicate glass is used for laboratory-scale units.

- Orientation: Most wiped film evaporators operate in a vertical configuration with feed entering at the top. The vertical orientation leverages gravity, which improves film movement and residue discharge.

- Heating Mechanism: A heating jacket provides heat for the evaporator using thermal fluid (oil, steam, or electric heating elements). It has control systems for uniform heat distribution and precise temperature.

- Vacuum Compatibility: A vacuum-tight construction is essential to enable operation at pressures ranging from atmospheric down to 0.001 mbar for extremely sensitive materials.

Types of Film Evaporators (and How WFE Differs)

Type | Key Feature | Limitation |

Falling Film Evaporator |

|

|

Rolled Film Evaporator |

|

|

Wiped Film Evaporator |

|

|

Short Path Distillation Unit |

|

|

Applications of Wiped Film Evaporators

Wiped film evaporators have applications across industries, including:

1. Pharmaceuticals: Wiped film evaporators are excellent at purifying active pharmaceutical ingredients (APIs). They are critical for removing solvents from drug formulations.

2. Chemicals and Petrochemicals: These evaporators can easily handle the concentration of reactive monomers that can easily clog conventional evaporators.

3. Food and Flavors: Wiped film evaporators concentrate fruit juices, extract essential oils, produce natural flavor compounds, and remove off-flavors from food ingredients without destroying delicate aromatic profiles and nutritional components.

4. Cannabis and Hemp Industry: In cannabis distillation, wiped film evaporators are needed for producing high-purity cannabinoid isolates and purifying crude oils.

5. Perfumes and Fragrances: These systems have precision controls that can gently extract and concentrate volatile aromatic compounds from natural sources.

6. Waste Solvent Recovery: Wiped film evaporators are designed to be efficient and economically recover and purify contaminated solvents from industrial waste streams.

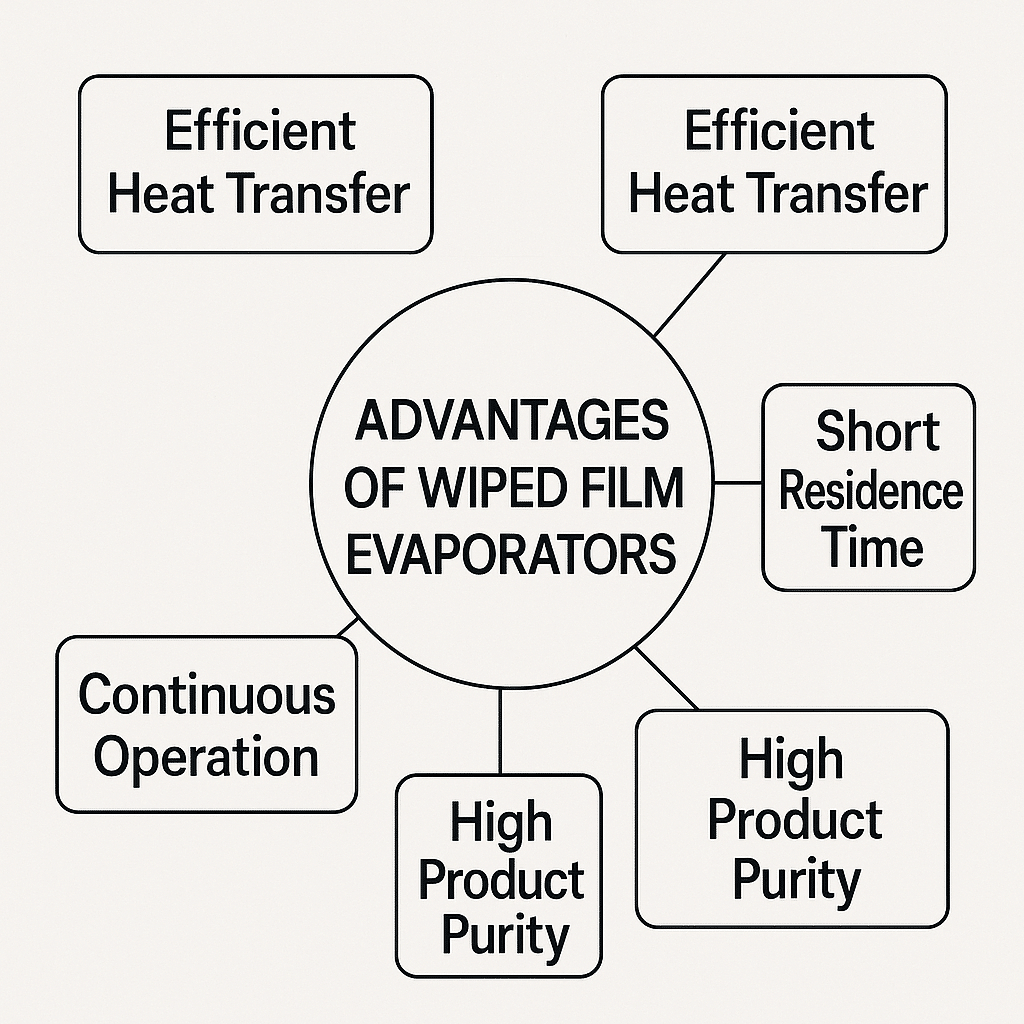

Advantages of Wiped Film Evaporators

There are several reasons to choose wiped film evaporators over conventional equipment.

1. Efficient Heat Transfer: The thin film principle increases the area of contact, offers excellent thermal conductivity, and enables rapid heat transfer and evaporation.

2. Low Operating Pressure: Vacuum operation significantly reduces boiling points, allowing the system to operate more efficiently and distill heat-sensitive materials at temperatures 100-200°C below their atmospheric boiling points.

3. Short Residence Time: Rapid movement of source materials minimizes thermal exposure and preserves product quality.

4. High Product Purity: A wiped film evaporator can achieve excellent separation efficiency, producing distillates with purities exceeding 95-99%.

5. Minimal Fouling: Continuous wiping action prevents the buildup of deposits on heat transfer surfaces. It maintains consistent performance even with fouling-prone materials.

6. Continuous Operation: Wiped film evaporators maintain steady-state processing with continuous feed and discharge.

Limitations and Considerations

As with any equipment, these evaporators have their limitations.

1. Higher Initial Cost: Wiped film evaporators don’t come cheap. A complex system of rotating components, precision machining, vacuum systems, and specialized materials makes them highly expensive.

2. Maintenance Needs: More moving parts, such as the rotating wiper system and precision bearings, require periodic inspection, lubrication, and replacement.

3. Feed Limitations: While wiped film evaporators handle viscous materials well, high-viscosity feeds could damage wipers.

Selecting the Right Wiped Film Evaporator

Decide to buy a wiped film evaporator based on these considerations:

- What is the nature of the feed material – thermal sensitivity, viscosity, and chemical properties

- Calculate the required throughput capacity and your production volumes requirement

- Consider the desired purity levels

- Assess utilities cost, including heating medium, cooling water, and electrical power

Maintenance and Operational Tips

- Regularly inspect wiper blades for wear

- Monitor vacuum system performance daily

- Implement a preventive maintenance schedule for mechanical seals, bearings, and drive systems

- Clean all surfaces thoroughly to prevent cross-contamination

- Keep detailed operating logs tracking temperatures, pressures, flow rates, and residence times

Conclusion

Wiped film evaporators are an evolution of conventional equipment, excellent for handling heat-sensitive, high-value, or viscous materials. Producers should understand the working principle of the wiped film evaporator and carefully consider their specific process requirements when selecting one. These systems are efficient but come at a substantial cost; therefore, consideration of their advantages and limitations is mandatory.