With the evolving cannabis market, therapeutic and recreational consumers expect products of the highest quality. One of the challenges producers face is providing consistency in their products, ensuring customers always experience the same effects. Choosing the correct strain and ensuring the potency level is not enough; cannabis homogenization is also essential.

In this article, we will explore homogenization, what cannabis homogenizer types are, and how manufacturers use them to create stable, potent, and uniform products.

Sections

ToggleUnderstanding Cannabis Homogenizers and Their Importance

What is Homogenization in Cannabis Processing?

Homogenization is breaking down the cannabis particles to a uniform size and distributing them evenly throughout a solution to create a stable, consistent mixture.

How is it different from blending or emulsifying?

- Blending: It is simply combining ingredients without necessarily breaking down particle structures.

- Emulsifying: It doesn’t break down particles but rather mixes immiscible liquids (like oil and water) that would usually separate.

- Homogenizing: It mechanically breaks down particles to microscopic or nano-size and evenly distributes them.

Key Applications:

- It helps create water-soluble cannabinoid formulations for faster absorption

- Used in the processing industry for producing stable emulsions for beverages and tinctures

- Used for maintaining consistent potency distribution in topicals and edibles

- Homogenization improves the bioavailability of active compounds in products

- By enhancing product stability, it extends shelf life

Why It Matters:

- Even Distribution: Homogenizing cannabinoids and terpenes ensures they are uniformly dispersed throughout the product.

- Consistent Potency: Even distribution of cannabinoids in a product delivers consistent potency from one serving to the next.

- Improved Stability: Improve homogeneity that prevents separation and extends the shelf life of cannabis products.

- Regulatory Compliance: In the food and medical industry, it helps meet strict requirements for product consistency and accurate labeling.

Types of Cannabis Homogenizers

As the product diversity in the cannabis industry is increasing, there are different types of homogenizers available today to choose from. Let’s understand the types of homogenizers and their underlying mechanisms.

1. High-Pressure Homogenizers

Mechanism: This type of homogenizer uses high pressure to break down particles by forcing the product through nanogaps

Best for: Creating nanoemulsions for beverages, tinctures, and oils.

Pros:

- Produces tiny particle sizes (often below 100nm)

- Ideal for transparent, shelf-stable emulsions

Cons:

- Expensive equipment

- It may require more energy and maintenanc

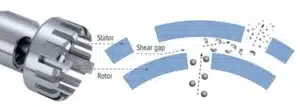

2. Rotor-Stator Homogenizers

Mechanism: It uses a rotor inside a stationary body to create high shear forces, essentially churning the particles to a uniform size

Best for: Medium-viscosity cannabis products such as creams, lotions, and semi-liquid formulations

Pros:

- Versatile cannabis homogenizer suitable for many product types

- Available in various sizes from bench top to production

Cons:

- Not as effective as high-pressure systems

- It may require multiple cycles for optimal results

3. Ultrasonic Homogenizers

Mechanism: This type of homogenizer uses high-frequency sound waves to break down particles

Best for: Low-scale production, research, and development

Pros:

- Best homogenizer for laboratory use and product development

- Minimal heat generation preserves temperature-sensitive compounds

Cons:

- Not adequate for large-scale production

- Not effective for highly viscous materials

4. Bead Mill & Mechanical Homogenizers

Mechanism: Mechanical homogenizers use grinding media (beads) and mechanical agitation to crush and disperse particles.

Best for: Excellent for breaking down plant material and creating suspensions

Pros:

- Pre-processing of raw plant material

- Can handle higher-viscosity products

Cons:

- Limited particle size reduction

- Grinding media can contaminate product

Key Uses of Homogenizers in Cannabis Processing

Homogenizers are used across almost every product category in the cannabis industry:

- Nanoemulsions for Beverages: Helps create stable, clear cannabis-infused drinks that offer improved bioavailability of compounds with rapid onset.

- Topicals, Creams, and Lotions: Consistency produced by a cannabis homogenizer is essential for consistent cannabinoid distribution throughout topical products.

- Tinctures and Oils: The reduced particle size enhances the absorption rate and creates the uniform suspension necessary for tinctures and oils.

- Vape Liquid Production: For vaping, consistent formulations with evenly distributed cannabinoids and terpenes are essential. These can be created with homogenizers, ensuring a consistent experience.

- Product Development & Testing: It can be used for product development and testing due to precise control.

How to Choose the Right Cannabis Homogenizer

Multiple types of homogenizer products make choice confusing; here’s how you can make the decision:

1. End Product Needs

- The particle size needed for the final product

- For transparent cannabis products, more aggressive homogenization is required

- Formulation viscosity determines the suitable technology

2. Production Scale

- The production volume and future expansion plans

- Batch size of each production cycle

- Production level for meeting market demand efficiently

3. Cost and Maintenance

- Price can vary drastically between different types of homogenizers

- Replacement parts availability

- Energy consumption

4. Ease of Use and Cleanability

- The tool must be easy to clean to avoid contamination

- Any special cleaning agents or solvents are required for cleaning

- Training needed to operate the tool

5. Compliance and Materials

- For food-grade products, FDA-grade materials should be used

- GMP compliance features for regulated production

- Must be approved for R&D

Common Mistakes to Avoid

With homogenization in cannabis processing, some common mistakes should always be avoided:

- Using the Wrong Type: The homogenizer technology must match your product specifications, essential for effective processing. The wrong type of homogenizer can cause wasted materials and substandard products.

- Ignoring Scale-Up Needs: Not planning to scale the operation can force costly replacements later.

- Neglecting Cleaning Requirements: Inadequate cleaning between batches leads to cross-contamination, resulting in product inconsistency and potential compliance issues.

- Underestimating Operator Training: To use a cannabis homogenizer effectively, proper training is essential. It will ensure consistently achieving desired results.

Conclusion

Selecting the right cannabis homogenizer is essential for product quality and consistency, manufacturing efficiency, and regulatory compliance. From nanoemulsions for fast-acting beverages to developing innovative new formulations, homogenization plays a critical role in the manufacturing process. That’s why understanding the different types of homogenizers available in the market is crucial for product manufacturers. It helps them make informed decisions that align with their product goals and production requirements.