The first step to creating high-quality oil is cannabis extraction. Raw extract is filled with unwanted materials like lipids, waxes, and fats that cloud the oil, thus affecting its flavor and causing failures. This article will take you to the purification process called winterization, which is the key to unlock a potent, stable, and pure cannabis concentrate.

Sections

ToggleWhat is Cannabis Oil Winterization?

It is the post-extraction purification process that is designed to remove the unwanted compounds. This includes dissolving crude extract in ethanol and then subjecting it to very cold, freezing temperatures. Further, this leads to solidifying of waxes, lipids, and fats for further filtration. All this results in winterized oil, which is cleaner.

Why is Winterization Essential for Cannabis Extracts?

Winterization is important for cannabis extraction for a lot of reasons, including:

- Potency and clarity: Waxes and lipids make a cloudy appearance and dilute the potency of cannabinoids as well as terpenes. Winterization removes all these impurities, leading to crystal clear oil, representing strength.

- Better flavor and experience: The undesirable plant compounds contribute a green, harsh flavor to the oil. When these unwanted elements are removed, winterization offers a cleaner, smoother taste to enhance the consumption experience, ingested or vaped.

- Prevents clogging in vape cartridges: This is the most important reason winterization is important. The waxes and fats that solidify will even solidify at room temperature when it is inside a vape cartridge, resulting in ineffective vaporization, clogging, and a bad experience for the user.

- Oil becomes more stable and compliant- Oil consistency and stability are crucial for recreational and medical purposes. Winterization makes a chemically stable product that has a longer shelf life. Also, a lot of regulatory bodies need products, mainly vape cartridges to meet purity and clarity standards which cannot be achieved without the winterization process.

Click here to know more about Cannabis Winterization Process: The Complete Guide

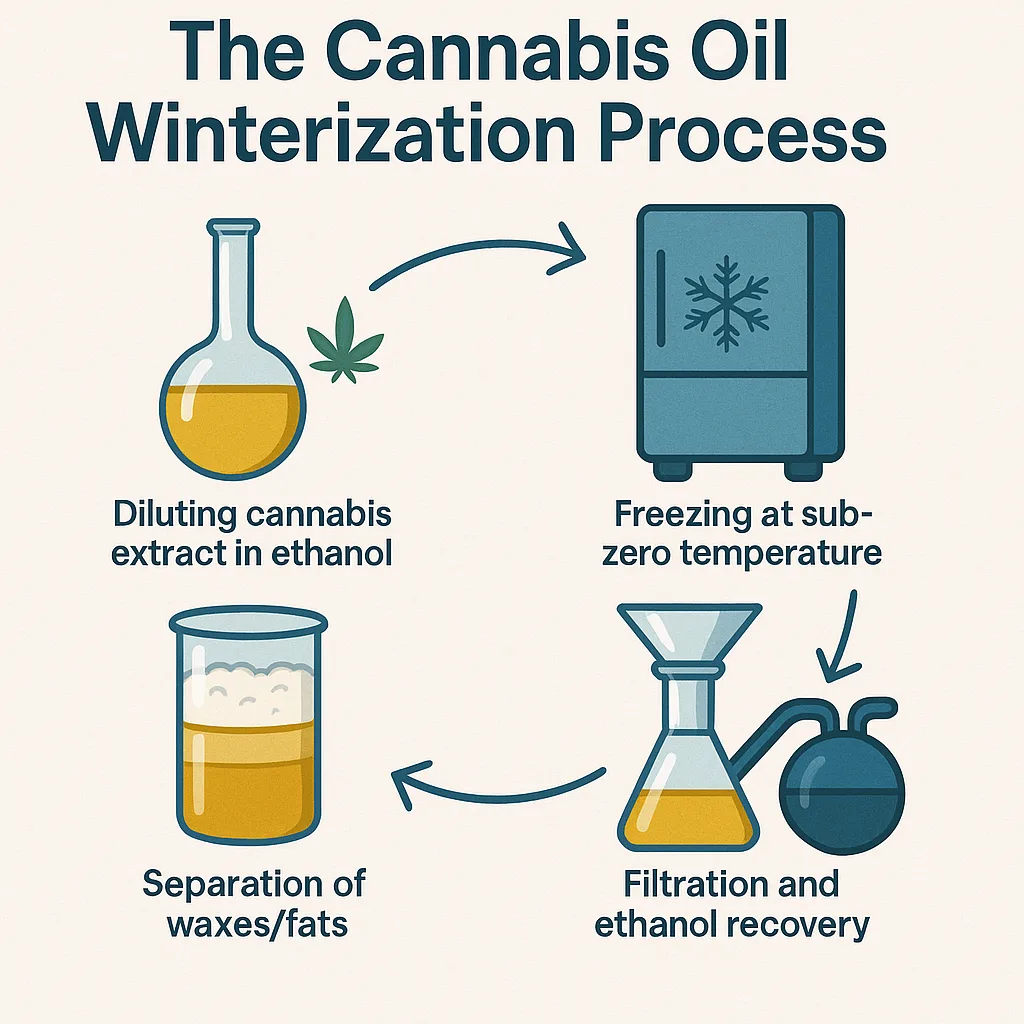

The Cannabis Oil Winterization Process

The process of winterization is methodical and needs precision. The steps involve:

- Diluting cannabis extract in ethanol: The crude, raw extract is mixed with 200-proof food-grade ethanol which further acts as a solvent, fully dissolving the extract and separating desirable from undesirable compounds.

- Freezing at sub-zero temperature: The combination of ethanol and extract is then placed in the freezer, between -20 and -40°C for at least 24 to 48 hours. This cold temperature then causes any non-desirable compounds to solidify and coagulate, forming a visible clump or frozen lipid layer.

- Separation of waxes/fats: When the freezing period is over, the mixture is then carefully removed from the freezer. As we see that the waxes and fats are separated from the non-purified oil and ethanol solution, while at the same time everything is extremely cold and prevents re-dissolving.

- Filtration and ethanol recovery: The mixture is then poured through a filter. This helps to capture the solid waste, allowing winterized oil to pass through. The last step is to use an ethanol recovery system to heat the solution and then evaporate the ethanol, which is there for reuse, leaving winterized, pure cannabis oil behind.

Common Equipment Used:

Some standard equipment used for the method includes magnetic stirrers, lab freezers, filter paper, recovery pumps, rotary evaporator and Büchner funnel with the vacuum flask.

Want to Perfect Your Cannabis Winterization Process?

Benefits of Winterized Cannabis Oil

- Higher Purity and Quality: This is indeed the most direct advantage that the product is free from contaminants, leading to an effective and more potent concentrate.

- Better Consistency Across Batches: The winterization process removes the variables like any seasonal alterations in plant lipid content, thus allowing the producers to create a product with the same viscosity, appearance and performance.

- Longer Shelf Life and Reduced Contamination Risks: Through removing the lipids and fats, winterized oil has an extended shelf life and maintains efficacy and flavor for a longer time.

- Industry Trust and Compliance: Producing stable, reliable and clear products that builds trust and is a negotiable requirement for any legal compliance.

Applications of Winterized Cannabis Oil

Winterized cannabis oil is used at various places to cater to different needs and requirements. Some of them include:

- Vape cartridges- This is the main application as the winterization oil is very thin to wick properly and is free of any lipids, not causing any clogging.

- Tinctures and edibles- Winterization process creates natural flavored oil perfect for infusing into various types of products without even giving off any weedy, strong taste.

- Concentrates and topical- Winterization is important for some products like distillates, wax and shatter to achieve the translucent appearance and purity. It further creates a smooth oil for topical, which can easily be absorbed by the skin.

- Pharmaceutical and therapeutic uses- Medical-grade products need the highest level of consistency and purity. Winterization is crucial for creating these standard doses and ensuring that the product is free from any unwanted plant matter.

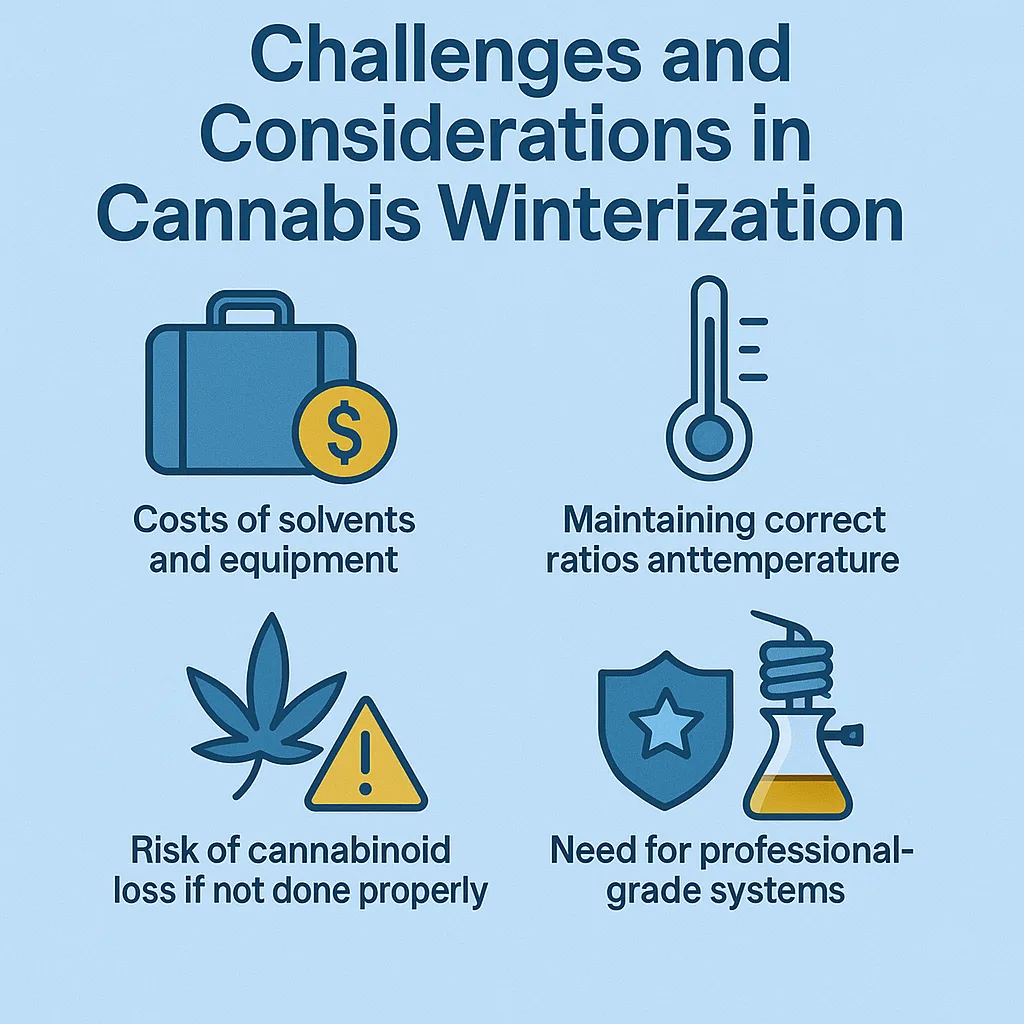

Challenges and Considerations in Cannabis Winterization

- Costs of Solvents and equipment- The winterization process needs significant investment in ethanol and lab equipment, such as the rotary evaporator, which is expensive for small-scale producers.

- Maintaining correct ratios and temperature- The ratio of oil to ethanol as well as maintaining ultra-low temperatures throughout are important for success. Any changes can result in incomplete purification.

- Risk of cannabinoid loss if not done properly- When not performed properly, some desirable compounds can be lost during filtration and even the ethanol recovery phases.

- Need for Professional-Grade Systems-Safe and correct ethanol recovery needs specialized equipment that is explosion-proof as well. Doing winterization without it is inefficient as well as dangerous.

Conclusion

The process of winterization is not just an optional refinement; it is in fact an indispensable step for producers looking to create a safe, premium cannabis oil product. By removing waxes, fats, and lipids, the winterization process transforms crude extract into a stable, potent, and versatile concentrate that meets the demands of today’s consumers and regulators. While it may present some technical challenges, the advantages of consumer satisfaction, quality product, and brand reputation make this a cornerstone of cannabis processing in modern times.