VTA Distillation Systems for Cannabis and Hemp Processing

Root Sciences’ VTA distillation systems are engineered in Germany and built specifically for processing CBD- and THC-rich crude oil into high-quality distillate. These wiped-film short-path units include an internal condenser, cold trap, heating and vacuum controls, and dedicated discharge systems for consistent operation. Select models feature borosilicate glass for clear visibility throughout the process, supporting reliable, efficient distillation for a wide range of finished products.

Lab Scale

VKL 75

The VKL 75 is a dependable, German-engineered distillation system designed to support steady, day-to-day production of high-quality cannabis distillate. Known for its efficiency and approachable entry point, this unit consistently delivers four to five liters of refined output per shift, making it a practical option for operations looking to increase productivity without added complexity. Its durable build and reliable performance make the VKL 75 a trusted choice for producing distillate used across a wide range of finished goods.

Commercial Scale

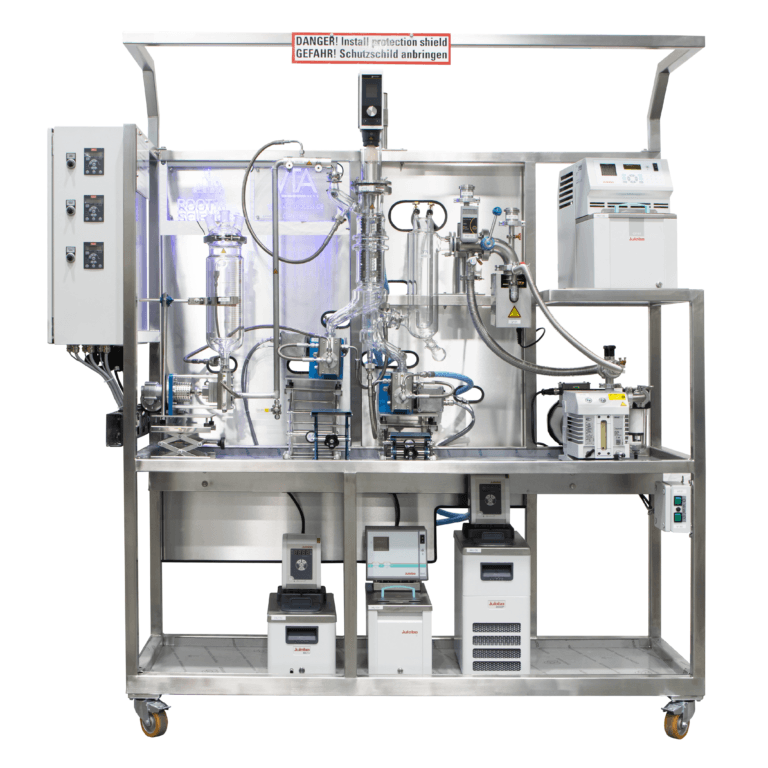

VKL 85

The VKL 85 is a German-engineered distillation system built for operations that need higher throughput and consistent daily performance. Designed for processing larger volumes of cannabis and hemp crude oil, it can support production rates of approximately 3 liters per hour, with higher outputs achievable under ideal conditions. Its glass evaporator allows clear visibility throughout the process, helping operators maintain uniform quality while increasing overall efficiency. The VKL 85 is a strong option for businesses looking to scale their distillate production with confidence.

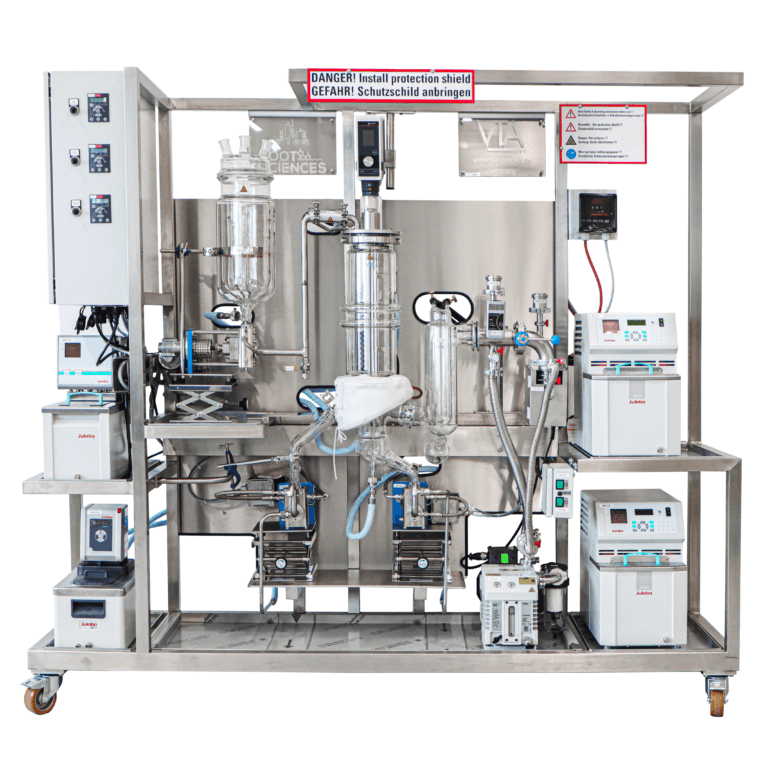

VKS 95

The VKS 95 is a German-manufactured wiped-film distillation system designed for larger-scale operations. With steady processing rates and the capability of handling up to approximately 5.5 liters per hour (and higher in optimal conditions) it provides consistent performance for refining cannabis and hemp crude oil. Built for reliability and extended run-times, the VKS 95 offers a robust solution for teams looking to elevate output while maintaining high quality and operational stability.

Industrial Scale

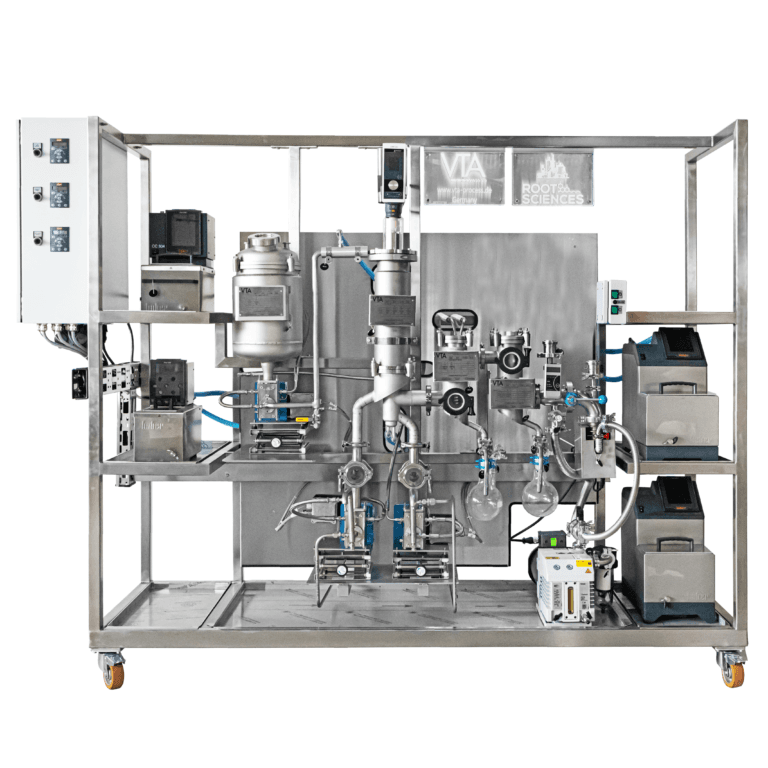

VKS 125

The VKS 125 is a high-capacity distillation system designed for large-scale processing of cannabis and hemp crude oil. With significantly higher throughput than smaller units, it supports continuous production and steady output for facilities aiming to expand their distillate capabilities. Its durable construction and dependable performance make it well suited for operations that require consistent results across long production runs.

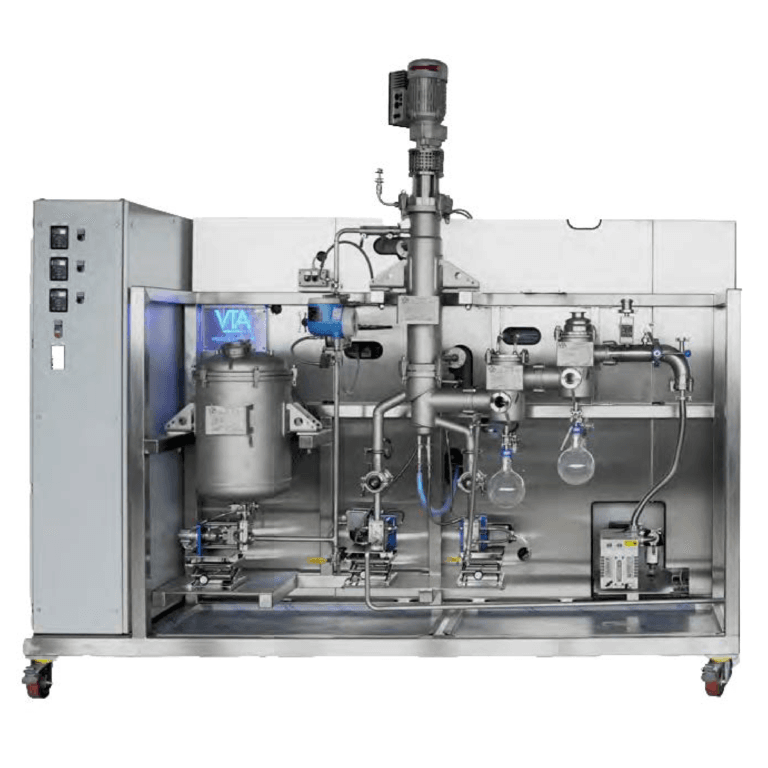

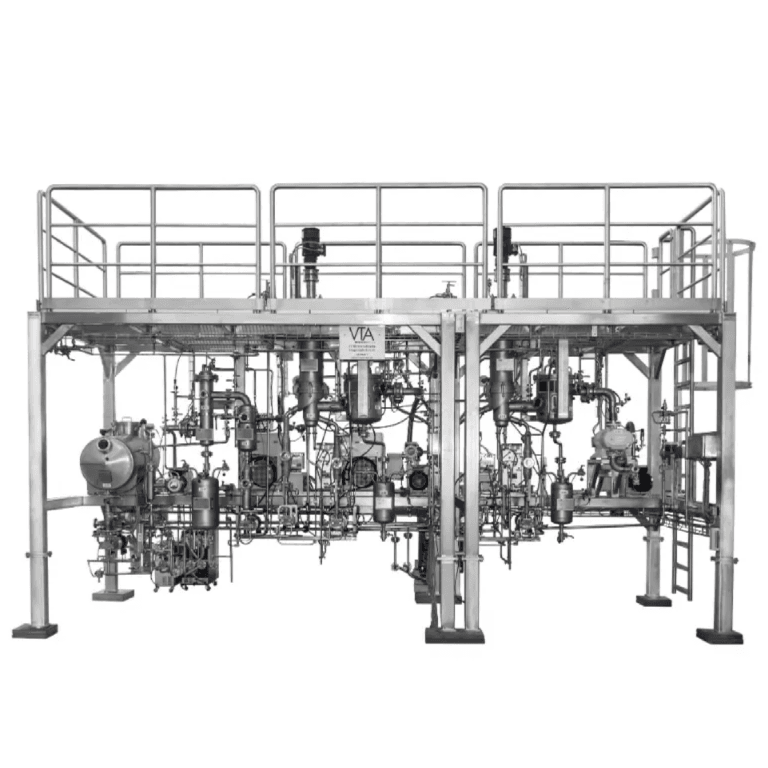

VK 200

The VK 200 is the industrial-scale distillation system from Root Sciences built for continuous high-volume cannabinoid processing. Engineered in Germany, it handles massive daily output and is ideal for facilities focused on large-batch production of CBD and THC distillate. The dual-stage configuration includes a degassing section to manage winterized and decarboxylated crude oils, supporting reliable performance while refining to high-purity outcomes. Operations using the VK 200 benefit from its streamlined design, consistent output, and strong fit for commercial-scale distillation goals.

VTA is a German manufacturer known for developing wiped-film and short-path distillation systems used across a wide range of thermal separation applications. Their equipment is designed to handle sensitive materials that require gentle and controlled processing, which makes it well suited for refining cannabis and hemp crude oil. In partnership with Root Sciences, VTA systems have been adapted to support dependable cannabinoid distillation by offering stable operating conditions, continuous processing, and clear visibility of key steps. This combination of engineering and practical functionality has made VTA a trusted option for facilities that need consistent results and a straightforward approach to producing high-quality distillate.

Wiped-film short path distillation is a method used to refine sensitive oils, such as cannabis and hemp crude oil, without exposing them to unnecessary heat for long periods. During the process, a thin layer of material is spread across a heated surface by rotating wipers. Because the film is extremely thin, it evaporates quickly and gently, which helps preserve the quality of the cannabinoids.

The evaporated material then travels a very short distance to an internal condenser, where it cools and becomes the distillate. Heavier compounds that do not evaporate remain separate and exit through a different path.

This design allows operators to separate desired components from unwanted ones in a controlled and efficient way, resulting in a cleaner, more refined product suitable for a wide range of finished goods.

| Model | Typical Throughput (L/h) | Maximum Throughput (L/h) | Scale | Key Notes |

|---|---|---|---|---|

| VKL 75 | 1.3 | 3.5 | Smaller scale | Good entry point for producers moving into continuous wiped film distillation with steady, day to day output. |

| VKL 85 | 2.8 | 4.25 | Small to mid scale | Higher throughput than the VKL 75 while retaining compact footprint and clear glass visibility for process monitoring. |

| VKS 95 | 5.5 | 14.27 | Mid scale | Designed for growing operations that need more capacity and longer continuous runs with consistent distillate quality. |

| VKS 125 | 15 | 20 | Large scale | High capacity system suited for facilities processing larger volumes of crude oil and supplying multiple product lines. |

| VK 200-40 | 40 | 50 | Industrial scale | Dual stage plant with a separate degassing section, built for continuous, high volume cannabinoid distillation at commercial scale. |

1. Designed for High-Purity Distillation of Viscous Oils

2. Extremely Short Residence Time

3. True High-Vacuum Performance

4. Continuous, Scalable Throughput

5. High Separation Efficiency

6. Automation, Repeatability & Process Stability

7. Robust German Engineering & Long Life

8. Flexible Multi-Stage Processing

9. GMP-Friendly Options

1. What is the main purpose of a VTA distillation system?

VTA systems are designed to refine cannabis and hemp crude oil into a cleaner, more concentrated distillate by separating desirable cannabinoids from heavier or unwanted compounds.

2. What makes wiped-film short path distillation different from other methods?

This approach spreads the material into a thin film and allows it to travel a very short distance to the condenser, reducing heat exposure and helping maintain cannabinoid quality.

3. What types of crude oil can be processed?

VTA equipment is built to handle winterized and decarboxylated cannabis or hemp crude oil containing CBD, THC, or other cannabinoids.

4. Do these systems run continuously or in batches?

VTA units are designed for continuous operation, allowing steady production and supporting higher throughput when compared to batch-based systems.

5. Are the systems difficult to learn or operate?

Operators generally find the systems straightforward once familiar with the workflow. Clear access on select units and consistent operating conditions contribute to a manageable learning curve.

6. How much distillate can a VTA system produce?

Throughput varies by model, with smaller units supporting modest daily output and larger models capable of significantly higher production volumes. The landing page can include throughput details for each system.

7. What maintenance is required?

Routine cleaning, seal checks, and periodic component inspections help keep the system running smoothly. Many operators schedule proactive maintenance to ensure reliable long-term performance.

8. Can VTA systems support large-scale production?

Yes. VTA offers equipment sizes ranging from small-scale production units to high-volume industrial systems, allowing facilities to scale as demand increases.

9. What kind of distillate quality can be expected?

When operated correctly, VTA systems can produce consistent, high-purity cannabinoid distillate suitable for edibles, concentrates, topicals, and other infused products.

10. How long do these systems typically last?

VTA units are built for durability, and with proper care and routine maintenance, they can remain in service for many years—even in high-use production environments.