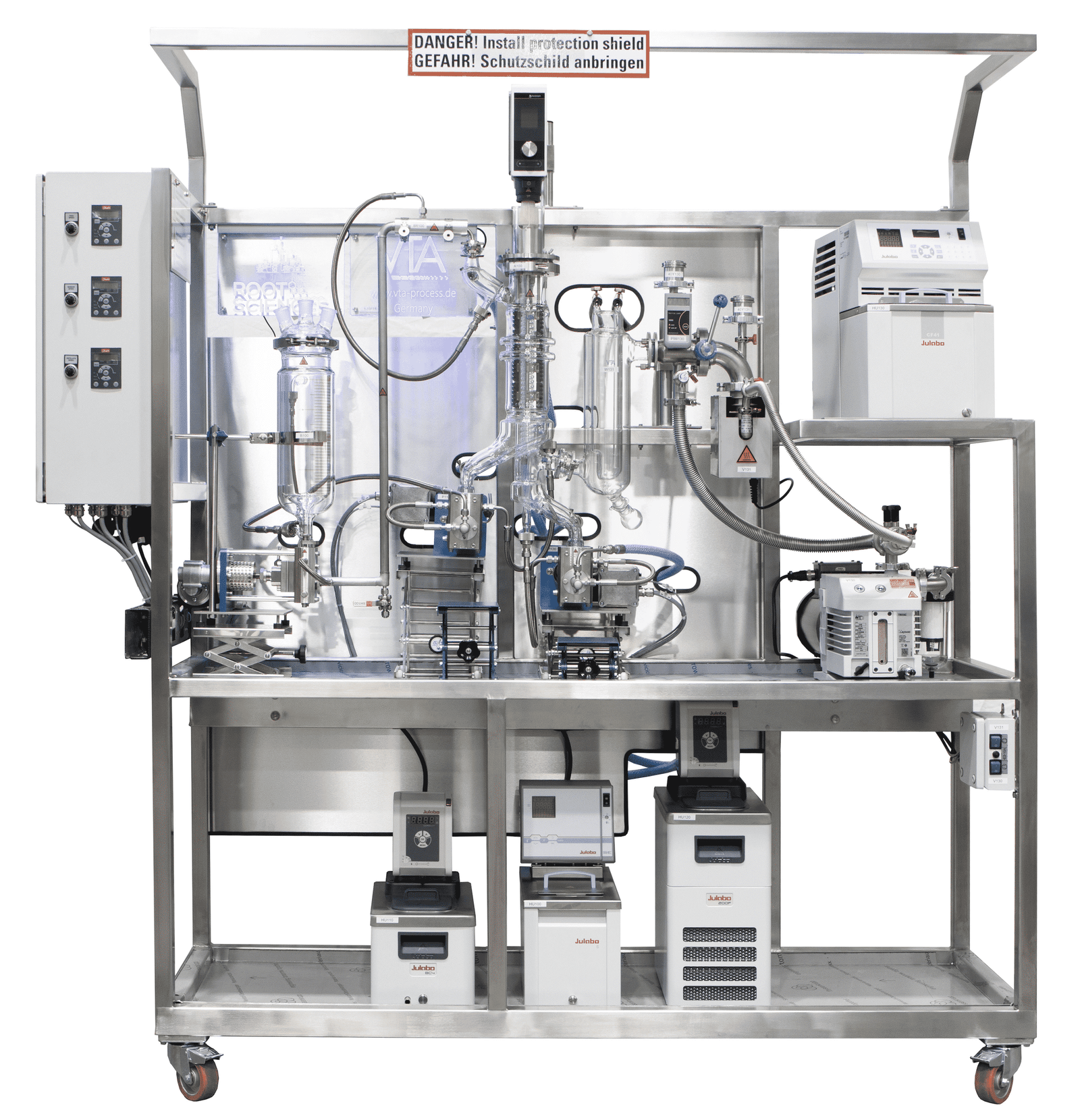

VKL 75 Wiped-Film Short Path Distillation System

key features

Throughput Capability: Typically 1.3 L/h, Maximum of 3.5 L/h

Optimal Yields and Potency: Finished distillate contains up to 99% total cannabinoids

Fully Jacketed System: Heated from start to finish, negating the use of heating tape or heat guns to keep product moving through the system

True Continous Feed: Integrated pumps for precise operator control over feed and discharge rates, allowing for true continuous operation, dispensing finished product to atmosphere

GMP Ready: Optional GMP package includes FAT, SAT, IQ, OQ — equipment can be further customized according to your URS to meet any local or international GMP requirements

High Visibility Processing: Transparent glass system enables operators to maintain optimal processing control by observing conditions inside the evaporator body

Expert On-Site Training: Instructions for operation of equipment and proprietary parameters for producing distillate are included with purchase

Wiped-Film Short Path Distillation Equipment

Root Sciences’ wiped-film molecular distillation plants are specifically intended for the processing of cannabis and hemp crude oil, with honest and accurate throughput/yield rates reflecting that.

Designed and manufactured in Germany, these machines are expertly engineered to produce distillate that can be used in a wide variety of products commonly found on the market today.

The VKL 75 is one of the most economical options on the market today for reliable non-stop production of high-potency distillate.

Technical Specs

| Maximum Feed Rate | 3.5 L/h |

| Typical Throughput | 1.3 L/h |

| Evaporator Surface Area | 0.05 m² |

| Power Requirements | 1Φ 230 V, 60 Hz |

| Stages | Single |

| Dimensions (L x W x H) | 7.4’ x 2.0’ x 6.0’’ |

| Certification | UL ready (all necessary individual components are UL listed) |

| Warranty | 1 year (excluding glass and vacuum system) |

| Materials Used | 316 stainless steel, borosilicate glass, graphite wiper blocks |

| Options | 5 L Feed vessel, Immersion chiller for cold trap, Separate heater for residue discharge arm, GMP package to include IQ, OQ, FAT, SAT, Heated transfer hose to connect multiple units in series |

ROI/Payback Period

Below are conservative calculations that can be expected with the VKL 75:

| Material | Cannabis | Hemp | Cannabis | Hemp |

| Daily Processing Time | 8-hour (one shift) | 24-hour continuous (three shifts) | ||

| Daily Crude Cost | $18,750 | $1,625 | $56,250 | $4,875 |

| Daily Distillate Yield | 5L | 15L | ||

| Daily Distillate Value | $32,500 | $2,715 | $97,500 | $8,145 |

| Payback Period | 10 days | 120 days | 3 days | 40 days |

Testimonials

In my experience working with Root Sciences, it has been great to say the least! Whenever we have an issue with our VTA I can always email, text, or call a number of people that are available to help/walkthrough troubleshooting techniques to help fix an existing issue or to make the system the most efficient possible. I am very appreciative of the customer service that is provided by the team and hope to continue our relationship well into the future.

JC MartinezMedMen

Root Science has been fantastic to work with. Our (VKL-70-4) is the most trouble-free piece of equipment that we have in our labs. Besides normal maintenance such as seals, washers, and gaskets it has never left us with a gap in our process. It is a pleasure to own such a quality piece of equipment!

Scott AgostinoExtraction Manager, Medmen

In the cannabis and hemp industry, there are a lot of promises to juggle and opportunities to navigate with no certainty of what outcome may actually be. Root Sciences has delivered a system that not only does EXACTLY what it has been proposed to do but the support that follows in unparalleled quality and industry knowledge… The customer service is not only extremely knowledgeable but well-rounded in navigating this growing industry. They provide the highest quality equipment with a dedicated team to help the customer grow with the industry… and that is an invaluable combination.

WayneFloyd’s of Leadville

I am jubilant to inform you that both systems have been running immaculately since your departure – you can tell an expert was at work… Very content with the service provided by Root Sciences.

Junior Lorenzo, Director of ProcessingLiberty Health Sciences

Highly satisfied with the equipment, training experience, durability, and ease of use. Many thanks from my team to yours.

Van SmitExtraction Manager, MedMen

Best distillate system in the world.

Ryan PinkskyDirector, TAIMA EXTRACTS

My partner and I have built and run several labs over the past few years, and VTA’s are the only distillation units we recommend to our clients, simply based on our experience with them. So again, thank you!

Christopher Covington

Root Sciences has been a wonderful partner to work with. Through the sales cycle, commissioning and operations they have been receptive, and helpful to Adastra's needs. In one instance, a critical component of our distillation plant was damaged and needed to be replaced. Kippy was quick to assist and we suffered less than 36 hours of down time. Keep up the good work Root Sciences!

Donald DinsmoreAdastra