Your Trusted Source for Cannabis Distillation Equipment

Root Sciences provides a full range of short path, wiped-film distillation systems through two trusted German-engineered lines: VTA and UIC. VTA represents our longest-standing distillation partnership and includes fully featured systems known for their consistent performance and long-term reliability in producing cannabis and hemp distillate. UIC, a newer addition to the portfolio, offers the same engineering foundation with configurations tailored for customers seeking a more cost-conscious entry point. Together, these two lines allow facilities of all sizes to choose the level of throughput, visibility, and features that best support their distillate production goals.

Lab Scale

KDL5

UIC

Engineered by UIC in Germany, the KDL5 is a glass wiped-film distillation system designed to give cannabis and hemp processors a clear, accessible entry into cannabinoid refinement. Its fully visible processing path helps operators understand each stage of evaporation and condensation, making it ideal for labs that want hands-on insight while producing clean, consistent distillate for a variety of product applications.

VKL 75

VTA

The VKL 75 is a compact wiped-film distillation system built for facilities that need consistent, manageable throughput. It supports routine processing of cannabis and hemp crude oil and produces a steady amount of distillate per shift without requiring extensive operational adjustments. Its straightforward design and dependable performance make it suitable for teams looking for a reliable system that fits comfortably into daily production workflows.

Commercial Scale

KD6

UIC

The KD6 is a stainless-steel wiped-film distillation system engineered by UIC in Germany for processors seeking dependable, everyday cannabinoid distillate production. With controlled film formation, semi-continuous operation, and durable construction, it offers a practical refinement solution for labs that want reliable performance and the efficiency of a compact, UIC-built distillation platform.

VKL 85

VTA

The VKL 85 is suited for facilities that need a step up in capacity from smaller units while maintaining predictable day-to-day operation. It handles larger volumes of cannabis and hemp crude oil and offers steady hourly throughput that supports mid-sized production goals. With clear process visibility and a layout that operators can monitor easily, the VKL 85 helps maintain consistent output as workflows grow.

KD10

UIC

The KD10 is a high-capacity wiped-film distillation system designed for processors who need greater throughput and consistent cannabinoid refinement across larger production runs. Built on UIC’s proven distillation platform, it offers the same reliable separation principles used throughout the line, making it a strong option for teams ready to scale their post-extraction workflows. While the full webpage is coming soon, our team is available to provide details, answer questions, and help you determine whether the KD10 is the right fit for your cannabis or hemp processing operation.

VKS 95

VTA

The VKS 95 is designed for facilities that require a noticeable increase in throughput while keeping production steady throughout longer operating periods. It processes larger volumes of cannabis and hemp crude oil and supports consistent hourly output suited for mid- to large-scale workflows. Its layout and build help maintain stable conditions during extended runs, making it a practical choice for teams expanding their distillate production capacity.

Industrial Scale

VKS 125

VTA

The VKS 125 is suited for operations that handle substantial volumes of crude oil and need a distillation system built for continuous, higher-capacity production. It supports significant hourly throughput and is structured to run for extended periods with steady performance. This unit fits well in facilities that have moved beyond mid-range processing and require equipment that can keep pace with large-scale demand.

VK 200

VTA

The VK 200 is the largest system in the VTA lineup and is intended for industrial environments where high-volume, continuous distillation is a core part of daily operations. Its multi-stage design accommodates substantial material input while maintaining consistent separation throughout the process. This configuration is useful for producers who rely on uninterrupted processing and need a system that supports significant output over long production cycles.

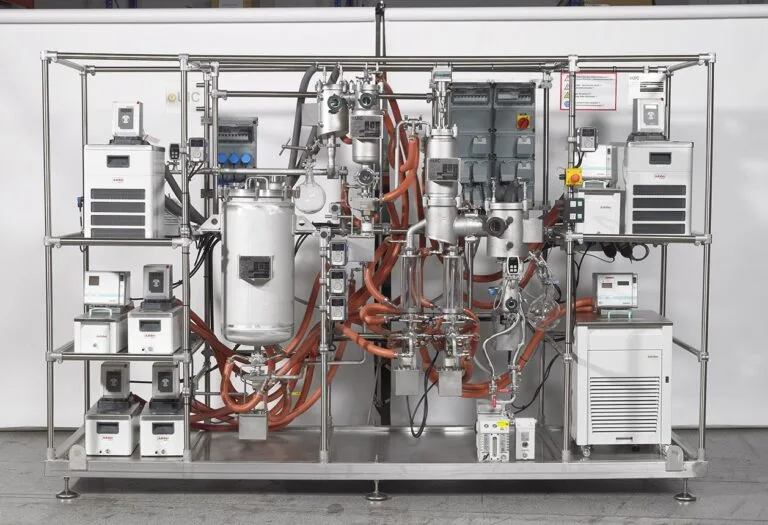

Custom Cannabis Distillation Equipment

VTA

Root Sciences offers custom-built VTA equipment options tailored to any scale of processing operations. Our cannabis distillation machines can be customized to meet the specific needs of even the largest processing facilities. Whether you require specialized features or unique configurations, our build-to-suit solutions ensure that your equipment is perfectly aligned with your production goals.

Both VTA and UIC deliver German-engineered wiped-film short path distillation systems for cannabis and hemp processing. Each line focuses on producing clean, high-purity distillate through continuous, controlled separation. The right choice depends on your operating goals, budget, and scale.

Where VTA Excels

- Flagship performance: Designed for facilities that want a feature-rich platform with advanced controls and a long track record in cannabinoid refinement.

- Scalability for growth: Well suited for teams planning higher throughput, multi-shift operation, or integration with broader automation.

- Proven in the field: Adopted by producers who value repeatable results across demanding production schedules.

Where UIC Excels

- Value and accessibility: Built for teams seeking dependable wiped-film distillation at a more accessible price point.

- Compact options: Helpful when space is limited or when an operation wants an entry-level or mid-scale system that can run daily with minimal complexity.

- Straightforward operation: Practical for labs that want consistent distillate quality with clear workflows and easy onboarding.

How to Decide for Your Facility

- Production targets: If your roadmap includes higher throughput and advanced automation, VTA is often the better fit. For entry-level to mid-scale production with strong value, consider UIC.

- Budget and timeline: UIC supports a cost-conscious start while meeting quality goals for cannabis and hemp distillate. VTA aligns with facilities investing in premium features and long-term expansion.

- Footprint and utilities: UIC offers compact configurations for tighter spaces. VTA provides options that integrate well in larger, growth-oriented layouts.

- Team experience: Newer teams tend to appreciate UIC’s approachable operation. Seasoned teams may prefer VTA’s advanced capabilities and configurability.

Bottom Line

Both VTA and UIC produce reliable, high-purity cannabis and hemp distillate with continuous operation and strong repeatability. Choose the line that best aligns with your current scale, future growth plans, and budget, and Root Sciences will support you through selection, installation, training, and ongoing maintenance.

Wiped-film, or short-path, distillation is a thermal separation technique that uses a thin film of oil spread across a heated surface under vacuum. The reduced pressure allows cannabinoids and other compounds to vaporize at lower temperatures, preserving delicate components and improving product purity. As vapors condense on an internal surface, they are collected separately from heavier materials left behind. This method is ideal for purifying cannabis and hemp extracts because it efficiently removes residual solvents, fats, and impurities while maintaining cannabinoid integrity. UIC systems apply this principle in a compact, automated format suitable for continuous operation in modern extraction labs.

| Model | Brand | Typical Throughput (L/h) | Maximum Throughput (L/h) | Scale | Key Notes |

|---|---|---|---|---|---|

| KDL 5 | UIC | ~2.0 | Varies | Small | Entry-level wiped-film system with a compact footprint. |

| VKL 75 | VTA | ~1.3 | ~3.5 | Small | Supports steady, routine distillation for smaller operations. |

| KD 6 | UIC | ~3.0 | Varies | Small to Mid | Designed for modest increases in throughput with simple operation. |

| VKL 85 | VTA | ~2.8 | ~4.25 | Small to Mid | Offers higher capacity than the VKL 75 with clear process visibility. |

| KD 10 | UIC | ~5.0 | Varies | Mid | Suitable for operators expanding beyond small-scale output. |

| VKS 95 | VTA | ~5.5 | Up to ~14 | Mid | Supports extended runs and stable processing for growing facilities. |

| VKS 125 | VTA | ~15 | ~20 | Large | High-capacity system built for large-scale production needs. |

| VK 200 | VTA | ~40 | ~50 | Industrial | Multi-stage design intended for high-volume, continuous operation. |

1. What is wiped-film distillation, and why is it used in cannabis and hemp processing?

Wiped-film distillation is a gentle refinement method that separates cannabinoids from heavier compounds using a thin film of oil across a heated surface. It is widely used because it preserves sensitive components while producing clean, consistent distillate for vape products, edibles, tinctures, and topicals.

2. How do UIC and VTA distillation systems differ?

Both manufacturers produce high-quality wiped-film systems, but they offer different designs, materials, and throughput ranges. UIC provides accessible glass and stainless-steel options, while VTA offers advanced German-engineered units known for their higher capacity and robust automation.

3. How do I choose the right distillation system for my lab?

The best fit depends on your target throughput, material volume, available utilities, and preferred level of automation. Smaller and mid-size systems suit developing labs, while high-throughput units support continuous industrial production.

4. Do all distillation systems work with the same type of feed material?

Most wiped-film systems process winterized or decarboxylated crude oil from cannabis or hemp extraction. Exact preparation requirements vary depending on system size, vacuum performance, and desired final product characteristics.

5. What products can be made using distillate from these systems?

Distillate produced on UIC and VTA systems is commonly used in vape formulations, edibles, tinctures, softgels, capsules, beverages, and a range of infused cannabis and hemp products.

6. How important is vacuum performance in wiped-film distillation?

Vacuum depth is crucial because it allows cannabinoids to evaporate at lower temperatures, which helps prevent thermal degradation. Both UIC and VTA incorporate specialized pumps and vacuum gauges to maintain stable operating conditions.

7. Are these systems difficult to operate?

Most units feature operator-friendly controls, clear workflows, and straightforward setup. VTA equipment often includes more advanced automation, while UIC systems emphasize accessible operation and real-time visibility depending on user preference.

8. Do the systems require frequent maintenance?

Routine cleaning, seal checks, and vacuum monitoring are standard for wiped-film systems. Preventive Maintenance Kits are available to help labs replace commonly used parts on a predictable schedule and minimize downtime.

9. Can these distillation systems scale with production growth?

Yes. Both lines offer multiple system sizes and throughput tiers, making it easy for labs to start with an entry-level model and expand to higher-capacity units as demand increases.

10. What support is available after purchasing a distillation system?

Root Sciences provides installation support, operator training, troubleshooting assistance, and access to maintenance kits and replacement parts to keep systems running reliably.