Across various industries, including pharmaceuticals and food processing, the extraction process is a crucial step. In cannabis processing, extraction is a cornerstone process to convert raw plant material into potent oils, waxes, and distillates. For producers, the decision to choose between a closed-loop vs an open-loop extraction system can be daunting.

In this guide, we explore both these systems, taking into account product quality, yield, safety protocols, regulatory compliance, and long-term profitability.

Sections

ToggleWhat Is Cannabis Extraction?

Cannabis extraction is the process of separating desirable compounds such as cannabinoids and terpenes from plant material. The process uses solvents like butane, propane, ethanol, or CO2 to remove unwanted substances such as chlorophyll and lipids. Cannabis extraction produces potent extracts ranging from shatter and wax to vape cartridge oils and distillates.

What Is an Open Loop Extraction System?

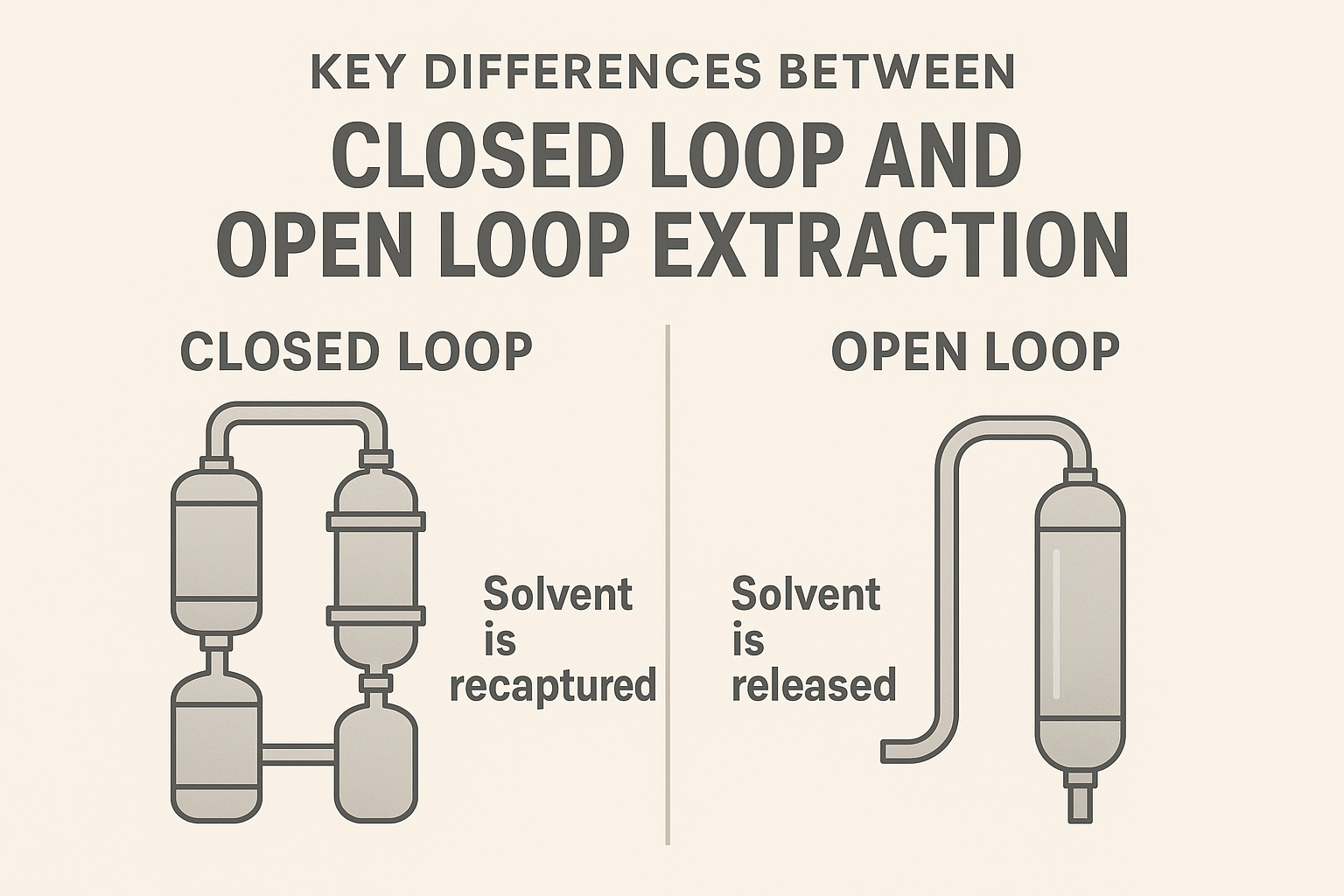

An open-loop extraction system is a setup in which solvents pass through cannabis material in a single direction. There is no recirculation or recovery of solvents, and they are discarded after extraction. It is a rudimentary approach that is now largely replaced by closed-loop systems due to severe safety and environmental concerns.

Key Characteristics:

- Solvent is used once and released into the environment without any recirculation

- Equipment investment is minimal, as the setup has basic tubes, containers, and pumps

- Exposure to uncontrolled solvent vapor poses an extremely high risk of explosion

- Minimal controlled systems without pressure regulation, temperature control, or safety monitoring systems

What Is a Closed Loop Extraction System?

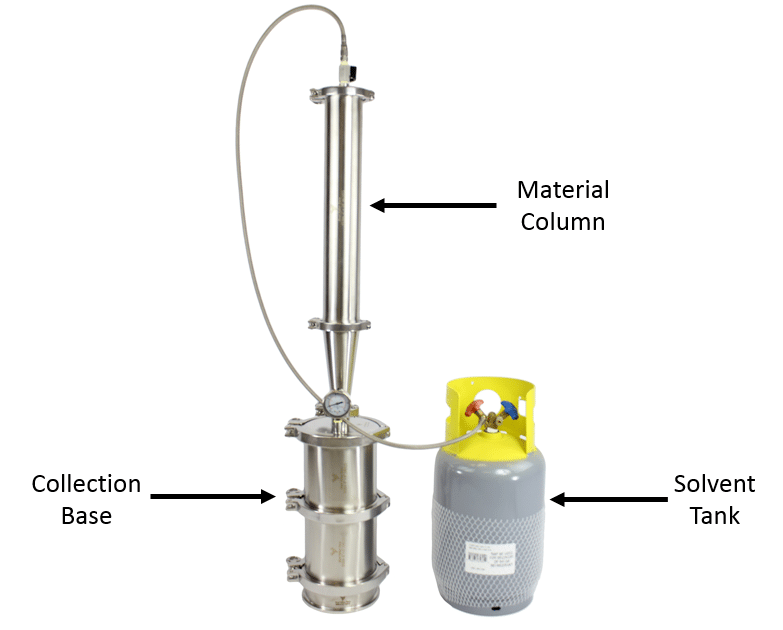

A closed-loop extraction system is a modern piece of equipment that is a sophisticated, sealed apparatus that recycles solvents within the system. The system captures, recovers, and recycles the solvent for continuous reuse. A professional-grade closed-loop extraction system comprises several key components: an extraction vessel, a solvent tank, a recovery pump, and a condenser, all contained within a sealed system. These extractors have precise pressure and temperature controls to optimize extraction efficiency.

Key Characteristics:

- Solvent remains contained through the entire extraction cycle, recovered and reused repeatedly.

- Sophisticated setup with pressure-rated vessels, safety relief valves, automated controls, and explosion-proof electrical components.

- High initial investment but delivers superior safety, efficiency, and regulatory compliance.

- Modern systems enable precise process control for temperature, pressure, and vacuum.

Key Differences Between Closed Loop and Open Loop Extraction

Feature | Open Loop Extraction | Closed Loop Extraction |

System Type | Single-pass with atmospheric venting | Sealed, recirculating with solvent recovery |

Safety Level | Extremely dangerous; high explosion/fire risk | Inherently safer with containment and monitoring |

Solvent Recovery | Zero recovery; 100% atmospheric release | 95-99% recovery and reuse capability |

Yield & Purity | Lower yields; inconsistent quality with contaminants | Higher yields; superior purity and consistency |

Cost | Low initial investment ($100-$1,000) | High initial investment ($5,000-$500,000+) |

Regulatory Compliance | Illegal in most jurisdictions; violates safety codes | Meets or exceeds regulatory standards; licensed operations |

Advantages of Closed Loop Extraction

There are several reasons why producers in the cannabis industry choose closed-loop extraction over open-loop extraction.

1. Enhanced Safety and Environmental Control

- As no solvent vapor is released, it completely eliminates the explosion risk associated with open systems.

- By not releasing toxic solvents into the environment, it protects both operators and the surrounding environment from harmful exposure.

2. Better Solvent Efficiency and Cost Savings

- Closed-loop systems recover 95-99% of solvents for reuse, which dramatically reduces operating costs.

- While the initial investment is high, it pays for itself through solvent savings in typically 6-18 months of operation.

3. Higher Purity and Yield

- More precise control over extraction parameters, such as temperature, pressure, and duration, results in better yield and quality

- Produces cleaner extracts with fewer residual solvents, plant waxes, and contaminants.

4. Regulatory Compliance

- Designed to meet regulatory requirements, closed-loop extractors meet fire codes, building codes, and cannabis-specific regulations.

- Facilitates the process to obtain necessary permits, insurance coverage, and business licenses.

5. Scalability

- These extractors are commercial-grade, designed to handle large volumes and maintain consistent quality.

- Make facility expansion and process optimization much easier due to their modular design and integration capabilities.

Limitations of Open-Loop Extraction

Keep in mind the limitations, too, before investing:

- Severe Safety Risks

Open-loop systems are prone to explosions and fires due to the uncontrolled accumulation of flammable solvent vapors.

- Poor Product Quality

With limited temperature and pressure control, these extractors produce inconsistent product quality, often contaminated with residual solvents, moisture, and plant material.

- Regulatory Non-Compliance

Open-loop extraction is explicitly illegal in virtually all jurisdictions with legal cannabis programs. Such extractors can subject operators to criminal prosecution and facility closure.

- Higher Long-Term Costs

Purchases of solvents without recovery create unsustainable operating expenses, rendering open-loop extraction economically inferior despite lower equipment costs.

Which Is Better for Cannabis Processing?

So, what will be the conclusion of the closed-loop vs open-loop extraction debate? A closed-loop extractor is a clear winner for any legitimate cannabis processing operation. Not only are these systems designed to be unequivocally superior, but they also make the cannabis extraction process sustainable. The open-loop extraction systems do offer a minimal initial investment option, but they expose operators to life-threatening hazards and incur product quality expenses.

Closed-loop extraction, despite higher upfront costs, delivers the safety, quality, efficiency, and compliance that make professional cannabis processing sustainable and profitable. The question isn’t whether closed-loop extraction is better, but rather which closed-loop system best fits your business needs.

Conclusion

For any commercial-scale producer, there is no real debate between closed-loop and open-loop extraction. Open-loop systems are amateur, dangerous, and unsustainable, making responsible processing impossible. Today’s legal cannabis industry demands closed-loop systems that protect operators, consumers, and communities. Closed-loop extractors deliver consistent, pure extracts while efficiently recycling the solvents into the system. While initial investment in closed-loop equipment may be substantial, it positions you for long-term success with scalable operations, regulatory compliance, and sustainable economics.