Closed-Loop BHO Systems for Cannabis & Hemp

Root Sciences offers industry-leading hydrocarbon extraction equipment tailored for cannabis and hemp processors focused on purity, terpene preservation, and efficient throughput. In partnership with Decimal Engineered, we provide closed-loop BHO extraction systems that meet rigorous safety, compliance, and production standards. Whether you’re creating live resin, shatter, or other solvent-based concentrates, our hydrocarbon solutions deliver consistent, high-yield results to support scalable processing operations.

Lab Scale

5.HX

The 5.HX is a compact closed-loop hydrocarbon extractor built for small to mid-sized cannabis and hemp operations. Compatible with butane, propane, or blended solvents, this system offers efficient recovery and terpene-rich concentrate production in a space-saving design. With ASME-certified components and precise temperature control, the 5.HX is a reliable choice for processors producing high-quality BHO products like shatter and live resin.

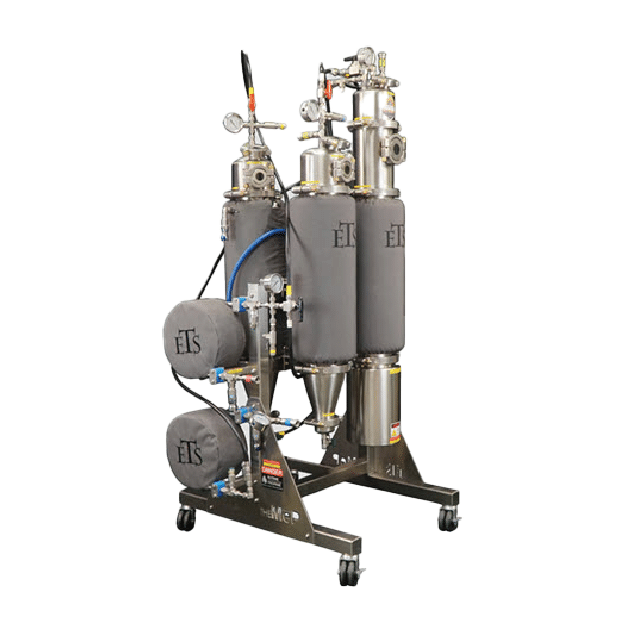

miniMeP

The miniMeP is a modular hydrocarbon extraction system designed for efficiency, safety, and scalability. This compact closed-loop BHO extractor is perfect for small to mid-sized operations, offering the same high-performance capabilities as larger systems while maintaining a streamlined footprint. With precision temperature control and industry-leading safety features, the Mini MeP ensures reliable, high-quality concentrate production—whether you’re refining your process or expanding your lab.

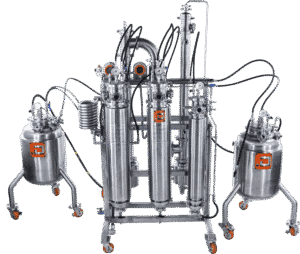

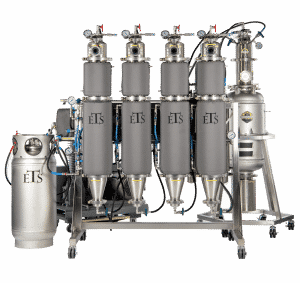

MEGA-miniMeP

The MEGA-miniMeP takes hydrocarbon extraction to the next level, combining the efficiency of the Mini MeP with increased capacity for larger-scale operations. Designed for processors looking to maximize throughput without compromising quality, this modular closed-loop system delivers high-purity BHO concentrates with consistency and control. Featuring advanced safety measures and precision temperature regulation, the MEGA-miniMeP is the perfect solution for labs seeking a scalable, high-performance extraction platform.

Commercial Scale

15.HX

The 15.HX is a mid-sized hydrocarbon extraction system designed for cannabis and hemp processors seeking greater throughput without sacrificing control or efficiency. This closed-loop unit supports butane, propane, and blend-based extraction, offering reliable recovery and consistent production of high-purity concentrates such as live resin, wax, and shatter. Its jacketed vessels and ASME-certified components ensure safe, regulated operation in GMP-ready environments.

40.HX

The 40.HX is a high-throughput hydrocarbon extraction system built for large-scale cannabis and hemp processing. Designed for use with butane, propane, or blended solvents, this closed-loop unit delivers efficient extraction and recovery while preserving cannabinoid and terpene integrity. Its robust construction, jacketed vessels, and ASME-certified components make it a dependable choice for operations focused on producing bulk BHO concentrates.

MeP 30

The MeP 30 is a powerful modular hydrocarbon extraction system built for efficiency, scalability, and compliance. Engineered for high-throughput operations, this closed-loop BHO extractor allows processors to maximize yields while maintaining exceptional product quality. With an intuitive design, advanced safety features, and precise temperature control, the MeP 30 is the go-to solution for labs looking to scale production while ensuring consistency and reliability in every run.

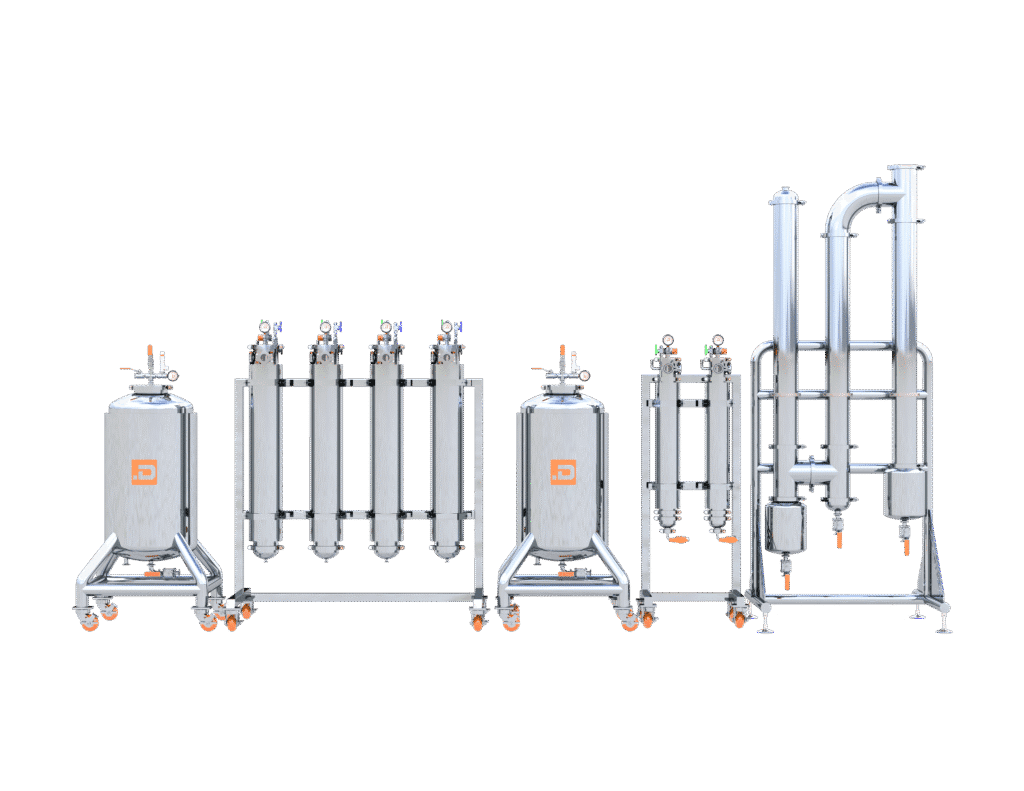

MeP XT70

The MeP XT70 is designed for large-scale hydrocarbon extraction, offering unmatched efficiency and throughput for high-volume processing. This advanced closed-loop BHO system provides operators with the power to produce premium concentrates while maintaining strict safety and compliance standards. With its modular design, precision temperature control, and robust construction, the MeP XT70 is the ideal solution for labs looking to scale up production without sacrificing quality or consistency.

Industrial Scale

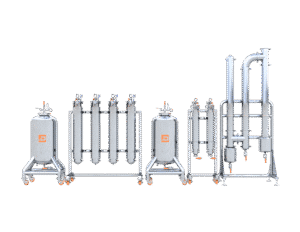

MeP XLE

The MeP XLE is engineered for the most demanding hydrocarbon extraction operations, delivering maximum throughput without compromising quality. This high-capacity closed-loop BHO system is designed for large-scale processors seeking efficiency, consistency, and compliance. With advanced safety features, precision temperature control, and a modular design for seamless scalability, the MeP XLE provides the performance and reliability needed to meet the growing demands of the extraction industry.

| 5.HX | 15.HX | 40.HX | |

|---|---|---|---|

| Ideal For | Small to mid-scale labs | Mid-scale commercial operations | High-throughput production |

| Solvent Compatibility | Butane, Propane, or Blends | Butane, Propane, or Blends | Butane, Propane, or Blends |

| Cycle Time | Approx. 30 minutes* | Approx. 30 minutes* | Approx. 30 minutes* |

| Capacity | Approx. 80 lb / 8-hour shift | 200+ lb / 8-hour shift | Approx. 40 lb per run |

| Solvent Recovery Rate | 1 lb/minute | 3–5 lb/minute | 8–12 lb/minute |

*Cycle time may vary depending on solvent blend, temperature, solvent-to-material ratio, and other processing conditions.

Hydrocarbon extraction is a solvent-based method used to separate cannabinoids and terpenes from cannabis and hemp plant material. It commonly uses hydrocarbons such as butane, propane, or a blend of both to dissolve desirable compounds and pull them from the biomass. This method is known for preserving terpene profiles and producing high-quality concentrates like live resin, shatter, and wax.

In cannabis and hemp processing, hydrocarbon extraction is favored for its ability to handle fresh frozen material and its compatibility with a wide range of post-processing techniques. The process is typically performed in a closed-loop system to maximize efficiency and minimize solvent loss, all while maintaining strict safety standards. When operated correctly, hydrocarbon extraction systems can consistently yield concentrates with robust flavor, high potency, and excellent clarity.

Hydrocarbon extraction begins by placing cannabis or hemp biomass into a sealed extraction column. A hydrocarbon solvent—usually butane, propane, or a mix—is then introduced under controlled pressure and temperature. As the solvent passes through the material, it dissolves cannabinoids, terpenes, and other desirable compounds, creating a cannabinoid-rich solution.

This solution is collected and routed into a separate vessel where temperature and vacuum are applied to remove the solvent. Solvent recovery units reclaim and condense the hydrocarbons for reuse, making the process both efficient and sustainable. The remaining extract can then be purged further or refined depending on the desired end product, such as live resin, diamonds, or sauce.

Throughout the process, modern hydrocarbon systems use jacketed vessels and precise temperature control to maintain product quality and reduce the risk of degradation. Compliance with industry safety standards, such as using ASME-certified components and proper ventilation, is essential to ensure safe operation in a licensed cannabis or hemp facility.

Hydrocarbon extraction offers several key advantages that make it a preferred method for producing high-quality cannabis and hemp concentrates. One of the most significant benefits is terpene preservation. Hydrocarbon solvents like butane and propane operate at low temperatures and are highly effective at capturing volatile compounds such as terpenes, which contribute to the flavor, aroma, and overall user experience of the final product.

This method is also highly versatile, allowing processors to work with dried or fresh frozen material and to produce a wide range of concentrate types—including shatter, live resin, budder, wax, diamonds, and sauce. This flexibility supports both small-batch craft processors and high-throughput commercial labs.

Efficiency and throughput are additional strengths. Closed-loop hydrocarbon systems are capable of fast cycle times and high solvent recovery rates, making them well-suited for continuous operation. These systems are also relatively compact, which allows for optimized space utilization in extraction labs.

From a cost perspective, hydrocarbon extraction is often more economical to set up and operate compared to other solvent-based systems. The lower operating pressures and temperatures reduce energy consumption and can simplify compliance when properly engineered for safety.

Finally, product quality remains a leading reason why many processors choose hydrocarbon extraction. It consistently delivers high-potency, terpene-rich extracts that retain the full-spectrum characteristics of the plant—an essential feature for many consumers and brands in today’s market.

1. What is hydrocarbon extraction used for in cannabis and hemp processing?

Hydrocarbon extraction is used to extract cannabinoids and terpenes from cannabis or hemp biomass. It’s commonly employed to create popular concentrates like live resin, shatter, wax, budder, and diamonds—products known for their potency, flavor, and aroma.

2. What types of solvents are used in hydrocarbon extraction systems?

Most systems use butane, propane, or a blend of the two. Each solvent has its own characteristics—propane is more effective at extracting lighter terpenes, while butane is ideal for capturing a broader spectrum of compounds. Blended solvents are often used to balance yield and terpene preservation.

3. Is hydrocarbon extraction safe?

Yes, when performed using closed-loop systems built to industry standards. Root Sciences offers hydrocarbon equipment that includes ASME-certified components and safety features such as jacketed vessels and recovery units. Proper ventilation, fire suppression, and operator training are also critical for safe operation.

4. What are the throughput capabilities of hydrocarbon extraction systems?

Throughput varies by system size. For example, the 5.HX is ideal for labs processing around 80 lb per 8-hour shift, while the 15.HX and 40.HX are better suited for mid- to high-volume operations, with capacities exceeding 200 lb per shift or 40 lb per run, respectively.

5. How long does a hydrocarbon extraction cycle take?

Most hydrocarbon extraction systems have cycle times around 30 minutes, depending on variables such as solvent blend, temperature, and material type. Efficient solvent recovery systems can help speed up turnaround between runs.

6. What kind of concentrates can I produce with hydrocarbon equipment?

Hydrocarbon extraction is incredibly versatile. Processors can create a wide range of products including live resin, cured resin, diamonds and sauce, shatter, budder, and terp sugar—depending on post-processing techniques and starting material.

7. What are the facility requirements for installing hydrocarbon extraction equipment?

Installations must comply with local fire codes, ventilation requirements, and building standards. Root Sciences can assist with facility design and layout planning to ensure your lab is properly configured for hydrocarbon extraction operations.

8. What support does Root Sciences provide with equipment purchases?

We offer more than just equipment—we provide end-to-end support, including system installation, operator training, and ongoing maintenance services. Our team ensures your hydrocarbon extraction system is up and running safely and efficiently.