Root Sciences’ VTA distillation plants are specifically intended for the processing of cannabis and hemp crude oil. Designed and manufactured in Germany, our cannabis distillation equipment is expertly engineered to produce a distillate that can be used in a wide variety of products commonly found on the market today.

Cannabis Distillation Equipment

VTA CANNABIS DISTILLATION SYSTEMS

Turnkey Solutions: Wiped-Film, Short Path Distillation Machinery For the Cannabis and Hemp Industries

OUR CANNABIS DISTILLATION EQUIPMENT LINEUP

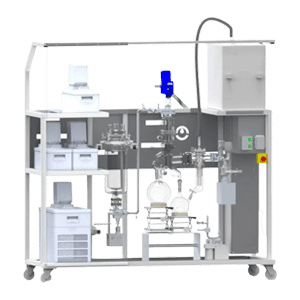

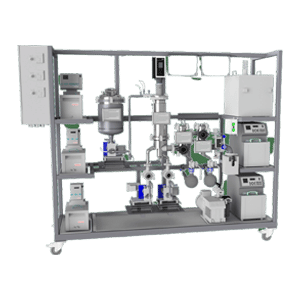

VKL 70-S

The VKL 70-5 is short path distillation equipment from Root Sciences that’s designed for the processing of high-quality distillates. Operating at a maximum capacity of up to 3kg/hour, it offers an efficient and effective solution for small to medium production scales. Using advanced technology, this unit ensures consistent, top-grade results, making it a preferred choice for many in the cannabinoid industry. Its compact design allows for a minimized footprint, optimizing lab space. With its advanced features, the VKL 70-5 is a testament to Root Sciences’ dedication to precision and quality.

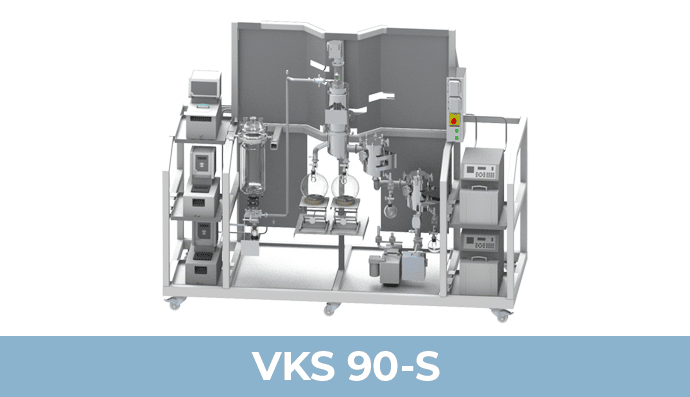

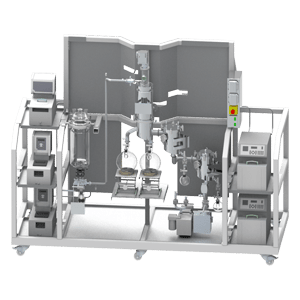

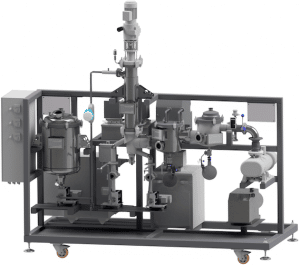

VKS 90-S

The VKS 90-S is an advanced short-path distillation system from Root Sciences designed to ensure the highest purity of distillates. With a peak processing capability of up to 5kg/hour, it’s tailored for those seeking efficient operations on a medium to large scale. Employing state-of-the-art technology, this equipment guarantees consistent, premium-grade outcomes, making it a top choice for professionals in the cannabinoid and essential oil industries. Its sophisticated design allows for optimal lab space utilization. The VKS 90-S is a testament to Root Sciences’ commitment to excellence and innovation.

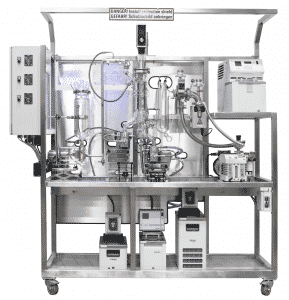

VKL 75

Designed and manufactured in Germany, these machines are expertly engineered to produce distillate that can be used in a wide variety of products commonly found on the market today. The VKL 75 is one of the most economical options on the market today for reliable non-stop production of high-potency distillate. The VKL 75 yields four to five liters of distillate per shift.

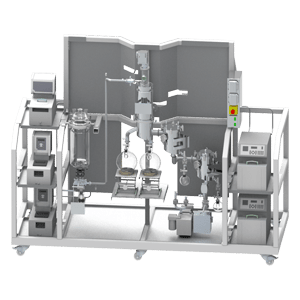

VKL 85

The VKL 85 is one of the highest throughputs fully glass wiped-film units on the market today for reliable non-stop production of valuable cannabinoid distillate. This machine is expertly engineered to produce a distillate that can be used in a wide variety of products found on the market today.

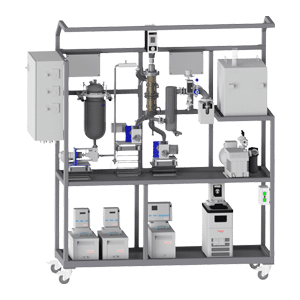

VKS 95

The VKS 95 is one of the highest quality wiped-film units on the market today for reliable non-stop production of valuable cannabinoid distillate.

VKS 125

The VKS 125 is one of the largest commercial cannabis distillation units on the market. Highly customizable, this unit can be tailored with options such as integrated advanced controls, and multiple distillation stages.

VK 200-40

At the top of Root Sciences’ standardized line, the VK 200-40 boasts the ability to produce approximately 280 liters of distillate per shift. This piece of cannabis distillation equipment is for processors who require extra-large production. Be sure to note the space requirement and differing electrical supply that this machine requires when planning a distillation space.

VTA CUSTOM CANNABIS DISTALLATION BUILDS

Root Sciences offers build-to-suit VTA equipment options for any scale processing operations. These cannabis distillation machines can be customized to suit even the largest of processing facilities.

OUR CANNABIS DISTILLATION EQUIPMENT LINEUP

VKL 70-S

The opening model in our VTA line, the VKL 70-S is the perfect industrial starter distillation center. If you don’t know what machine you need, the first metric you should consider is the amount of material you want to process per shift. The VKL 70-S yields four to five liters of distillate per shift.

VKL 75

Designed and manufactured in Germany, these machines are expertly engineered to produce distillate that can be used in a wide variety of products commonly found on the market today. The VKL 75 is one of the most economical options on the market today for reliable non-stop production of high-potency distillate. The VKL 75 yields four to five liters of distillate per shift.

VKL 85

The VKL 85 is one of the highest throughputs fully glass wiped-film units on the market today for reliable non-stop production of valuable cannabinoid distillate. This machine is expertly engineered to produce a distillate that can be used in a wide variety of products found on the market today.

VKS 90-S

The VKS 90-S is one of the most economical mid-sized options for reliable production of valuable cannabinoid distillate. The VKS 90-S yields around twelve liters of distillate per shift.

VKS 95

The VKS 95 is one of the highest quality wiped-film units on the market today for reliable non-stop production of valuable cannabinoid distillate.

VKS 125

The VKS 125 is one of the largest commercial cannabis distillation units on the market. Highly customizable, this unit can be tailored with options such as integrated advanced controls, and multiple distillation stages.

VK 200-40

At the top of Root Sciences’ standardized line, the VK 200-40 boasts the ability to produce approximately 280 liters of distillate per shift. This piece of cannabis distillation equipment is for processors who require extra-large production. Be sure to note the space requirement and differing electrical supply that this machine requires when planning a distillation space.

VTA CUSTOM CANNABIS DISTALLATION BUILDS

Root Sciences offers build-to-suit VTA equipment options for any scale processing operations. These cannabis distillation machines can be customized to suit even the largest of processing facilities.

DISTILLATION MODEL COMPARISON

| Model | VKL 70-S | VKL 75 | VKL 85 | VKS 90-S | VKS 95 | VKS 125 |

|---|---|---|---|---|---|---|

| Approximate Biomass Input (lb/shift) | 100-200 | 100-200 | 220-440 | 250-500 | 400-800 | 1100-2200 |

| Typical Throughput (L/h) | 1.3 | 1.3 | 3.0 | 3.5 | 5.5 | 15.0 |

| Evaporator Surface Area (m²) | 0.05 | 0.05 | 0.15 | 0.10 | 0.10 | 0.20 |

| Evaporator Material | Glass | Glass | Glass | Stainless Steel | Stainless Steel | Stainless Steel |

| Cold Trap Design | Single | Single | Single | Dual | Dual | Dual |

| Discharge Pumps | No | Yes | Yes | No | Yes | Yes |

| Electrical | 1Φ 230 V, 60 Hz | 1Φ 230 V, 60 Hz | 1Φ 230 V, 60 Hz | 1Φ 230 V, 60 Hz | 1Φ 230 V, 60 Hz | 3Φ 230 V, 60 Hz

3Φ 460 V, 60 Hz |

| Dimensions (LxWxH) | 6.6’ x 2.3’ x 6.6’ | 6.6’ x 2.3’ x 6.6’ | 7.2’ x 2.0’ x 7.5’ | 8.4’ x 3.3’ x 6.7’ | 8.2’ x 2.4’ x 6.5’ | 8.7’ x 4.1’ x 9.5’ |

System Advantages:

- Continuous feed (no need to break vacuum)

- Short residence time

- High evaporation rates

- Low processing temperatures

- Compact design

- Cannabinoid Separation

- Automated Controls

- Fully Jacketed for precise temperature controls

- Included: Short path evaporator (with internal condenser), cold trap, discharge systems (for distillate and residue), heating and vacuum system

- Main glass components are Borosilicate glass (allows view of concentrates during the distillation process)